What is CNC machining?

CNC Machining is composed of: CNC ( Computer Numerical Control) + Machining.

- ”CNC“ means entering a pre-program into a machine through a computer, to control the movement of tools and machinery.

- ”Machining“ are the processes to use suitable machines and cutting tools to remove material from the workpiece, and turn it into the shape you designed.

Talk more:

- NC (short for “Numerical Control”) was an industry standard and was quite popular in the 1950s.

- CNC is the son of NC, with the help of computer programming, it is higher in control accuracy, faster in production speed, and lower requirement of operators, more convenient to change the program, and can run for a long time.

- Although the cost of CNC is higher than NC, people are more willing to use advanced technologies that can improve efficiency and save manpower in the era of great industrialization. Its popularity started in the late 20th century.

- CNC machine: CNC machining center, CNC lathe, CNC router, CNC engraving machine, etc.

- CNC Machining processes include: turning, milling, tapping, honing, drilling, grinding, etc.

- With the popularization of CNC technology, CAD and CAM processes in the design field developed in the following, which made us can produce higher precision and more complex structure parts for industries, and the production efficiency is extremely high.

- Robot programming and the addition of robotic arms, now CNC machining can be fully automatic. This also solves the problem of insufficient productivity caused by the aging of the global population.

- Nowadays, people are always pursuing faster, higher, and stronger, and the machining field is no exception. In the long river of human history, I believe that machining technology and equipment will be constantly updated and iterated. Looking forward to a better future.

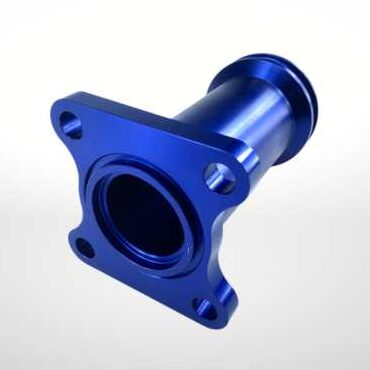

CNC Machining Parts with Different Materials

Material can be CNC Machining: Metal (such as aluminum, zinc, zamak, brass, iron, ductile iron, carbon steel, stainless steel, magnesium, titanium, and copper), Plastics (such as ABS, PVC, POM, PMMA, PPS, PEEK, PTFE, PU, PET, polycarbonate, polypropylene, rubber, and nylon), Wood(such as maple, basswood, black walnut, beech, cherry, and oak) and even some composites (such as carbon fiber and fiberglass)

All the product pictures below are our successful cases, Yontone can do much more for you. Everything can be machined.

New Energy Buses Parts

The parts are made of aluminum solid blocks, and round bars, like 6061-T6511-Extruded, 2024 T351, and 7075 T651.

Machining process: turning, milling

Surface treatment: color anodizing (red).

Brass Alloy Cnc Machining Hydraulic Valve Block

The parts are made of brass solid blocks, and round bars, like H59, H62

Machining process: milling, drilling

Surface treatment: no.

Welded Steel CNC Machining Bracket

The parts are made of steel solid blocks, and bars, like carbon steel, mild steel

Machining process: milling, turning, welding

Surface treatment: blackening

Parking Meter Housing with CNC Machining

The parts are made of zinc die casting, like zamak 3, zamak 5; Zinc alloy also has blocks & bars materials for machining.

Machining process: milling

Surface treatment: Transparent paint

Gearbox Housing with CNC Machining

The parts are made of aluminum die casting, like ADC12, A380, AlSi9Cu3, AlSi12Fe, ADC10, AlSi8Cu3Fe, A360, ADC3, ALSi10Mg

Machining process: milling

Surface treatment: powder coating

Sand Casting Cylinder Head with CNC Machining

The parts are made of ductile (grey) iron (steel) sand casting, like HT200, HT300, QT400, QT500, C45, 42CrMo

Machining process: milling

Surface treatment: sand blasting

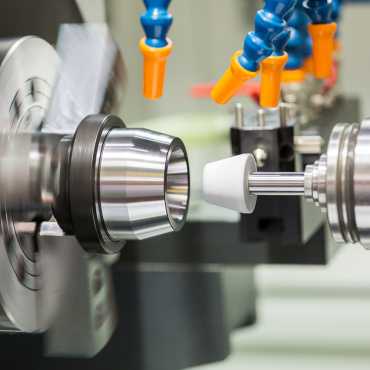

CNC Machining Processes

Yontone provides different types of CNC machining services as below: CNC milling, CNC turning, CNC drilling, CNC engraving, CNC grinding, CNC laser cutting, CNC routing, EDM, WEDM, etc.

The workpiece does not move, rotate the cutting tools and move against the workpiece.

After the cutter reaches the specified position, rotate the workpiece, to create cylindrical parts.

Rotate a cutting tool to remove the material, to create a design, pattern, or logo on the workpiece.

Use grinding wheels as cutting tools, and remove a small amount of material, to get better accuracy and finer surface.

The computer program controls the laser beam head moving, cuts through the material, and gets the desired pattern.

Use a fixture jig to position the workpiece, drill holes, and tap in the specified location.

More CNC Machining Parts

CNC machining parts can be used in different industries. Automotive, Hydraulic systems, Aerospace, Electronics, Telecommunications, Energy, New Energy, Marine, etc.

Yontone is an OEM company, every machining part are customized, and we accept drawings or samples for production purposes.

Advantages of CNC Machining Process

CNC machining provides great production flexibility since no mold needs to be created. This is especially beneficial for low-volume product runs.

CNC machining parts have higher dimensional accuracy when compared to those manufactured by casting or die-casting.

The machining process controlled by an advanced software computer ensures the stability of product size and tight tolerance.

Equipment can be easily operated, one person can handle 2-3 machines, this increases production capacity and reduces labor costs per product.

Self-Designed Fixtures

The fixture department of Yontone designs corresponding hydraulic fixtures for different shapes of products. Fixtures designed are convenient for employees to place products, and also ensure machining accuracy and production efficiency.

Custom PCB Cutters

Yontone’s tool department designs integrated PCB cutting tools according to the different product structures and tolerance requirements. The tool designed in this way ensures the concentricity, accuracy, and smoothness of the product meets very high requirements.

Quality Control

Usually, yontone’s QC department inspects the dimensions of products during and after the machining process.

- The operator checks the important dimensions of each machined product during production.

- Inspection personnel of the quality control department. Randomly select the products to do full-size measuring every hour during the machining process.

- Before warehousing, the whole batch of products shall be checked at the ratio of 5% ~ 20% ~ 100%. Specifically according to customer requirements, and also according to the importance of key dimensions.

Why Choose Yontone to Be Your CNC Machining Supplier

- Yontone has been specializing in precision hardware parts machining for over 15 years, offering a complete range of CNC machining services.

- Our experienced designers have over 8 years of industrial design experience and use excellent production technology.

- Delivery on time. We provide a stable delivery schedule and production plan at the beginning of each month.

- Our products are of high quality, and we provide material certification, ensuring machining accuracy of 0.01 ~ 0.005 mm (including parallelism, flatness, form, and position tolerance). We also offer a full-size report along with each shipment.

- With low minimum order quantities and reasonable pricing, we provide different quantity prices in our quotations. Additionally, we offer casting and die-casting production solutions to reduce costs for larger product quantities.

Wild Application Fields of CNC Machining Parts

Machined products are known for their high precision, strength, and easy assembly, and have found extensive applications in conventional automotive, new energy vehicles, and motorcycles.

Yontone machined many parts, like engine parts like cylinder heads, pistons, connecting rods, and crankshafts, as well as transmission components such as gears and shafts.

Additionally, machined products are used in brake components, suspension components, steering system components, and many others.

Aerospace products require high strength and lightweight, so we usually use lightweight materials to do machinings, such as titanium alloy and aluminum alloy.

- Aircraft engine components: turbine blades, fan blades, compressor discs, etc.

- Aircraft structural components: brackets, wing spars, stringers, etc.

- Landing gear components: brakes, struts, wheels, etc.

- Avionics components: connectors, housings, brackets, etc.

- Satellite components: mounting structures and antenna reflectors.

- Rocket engine components: nozzles, turbopumps, combustion chambers, etc.

Hydraulic cylinders and pneumatic cylinders are widely used in construction equipment, agricultural machinery, and aircraft fields.

Machined parts of hydraulic systems require high surface finish and precision. The interior of the hydraulic system considers the problem of air tightness and leakage issues, most products will be machined with block or bar materials.

Yontone produced many hydraulic parts, like cylinder barrels, piston rods, pistons, cylinder valve blocks, clevis, cylinder heads, rod glands, flange, and end caps.

In the traditional energy industry and the new energy industry, machining parts are widely used.

Yontone has experience in machining turbines, generators, and pump components.

- Wind power parts, like blades, hubs, shafts, and gears.

- Solar power parts, like frames, mounting brackets, and electrical connectors.

- In petroleum energy, some detectors and resistivity tools components are made by machining, also pumps, gears, shafts, drill bits, valves, and casing components.

CNC-machined products used in the medical field are mainly implants, instruments, and equipment accessories.

- Parts and screws used in hip and knee replacement.

- Dental implants and components.

- Components of diagnostic equipment (MRI) and scanning equipment (CT).