What is Casting?

Casting, also called metal casting, is a processing method that melts metal, pours it into a prefabricated mold, condenses, cleans, and ejects the required workpiece or blank.

In a broad sense, it includes low-pressure casting and high-pressure die-casting.

However, due to the increasing application of die-casting in auto parts, the amount of die-casting has increased dramatically. Die-casting gradually broke away and became an independent casting type.

Now we generally talk about casting, which refers to the casting method with little or no pressure and completely relying on gravity.

This includes low-pressure casting, gravity casting, sand casting, and other casting methods.

Common Cast Metals

1. Gray cast iron

2. Ductile iron

3. Malleable cast iron

4. Cast steel

Commonly used for casting non-ferrous metals

1. Brass

2. Tin bronze

3. Aluminum alloy

4. Zinc alloy

Casting Parts with Different Technique

The selection of the casting technique relies on factors including product size, metal material type, production volume, surface texture, density, and precision demands for the final product.

Yontone provides low-pressure casting, gravity casting, sand casting, and die-casting services to customers. We will recommend the most economical and practical production methods for customers based on the number of customer orders, the size of the parts, the final use of the product, and the requirements for air tightness.

Low-pressure casting is a bottom-up casting process. The metal solution is in a sealed crucible, which is connected to the mold inlet through a feed pipe. Then, by injecting pressurized gas into the crucible, the metal liquid enters the mold through the feed pipe, and finally cools and solidifies into the product we need.

Low-pressure casting products have high precision, a fine surface, high internal density, and almost no air holes, easy to be machined. They can be strengthened by heat treatment and have very good sealing properties. They are suitable for various hydraulic systems and automotive parts, engine components such as cylinder heads, cylinder blocks, pistons, and crankshafts, mechanical components such as machine tools, motors, instruments, and meters, etc.

Yontone is a supplier that mainly provides steel, iron and aluminum alloy low-pressure casting products.

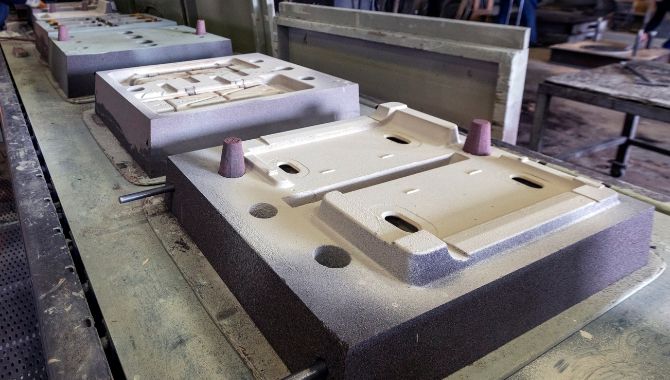

Sand casting, also known as sand mold casting, is a process of making a model of the product with sand and binder, pouring the molten metal directly into the mold inlet, and obtaining the product after cooling. Sand casting is very cost-effective and has almost no size limitations for products, so many super-large ship parts, aviation parts, and hydraulic structure parts are now completed through sand casting. Sand casting is also very affordable and has almost no minimum order quantity requirements, making it a good friend of small batch orders.

The disadvantages of sand casting are that the surface is rough and the internal porosity may occur due to the lack of pressure in the production process, resulting in poor air tightness after processing. However, it can make very thick products.

Yontone is a factory that mainly provides sand casting products of aluminum, iron, steel, copper, and ductile iron.

Gravity casting is a process of pouring molten metal into a permanent metal mold, completely relying on the gravity of the molten metal to fill the entire mold cavity, and obtaining a casting after cooling.

Gravity casting is divided into two types according to equipment: one is pure manual, which is relatively simple and is generally suitable for small and medium-sized products; the other is combined with a gravity casting machine. After the liquid is cast into the mold inlet, the machine will tilt 90 degrees to accelerate the flow speed of the liquid and assist in increasing the gravity. In this way, castings with a more compact internal structure and better performance can be obtained.

Yontone is a company that provides gravity-casting products of aluminum alloy, zinc alloy, and copper alloy to customers. Yontone also provides low-pressure casting, gravity casting, sand casting, and die-casting services to customers.

Casting With Different Materials

Many materials can be casted. Yontone can provide the following precision metal casting services:

- Aluminum casting:

- Iron casting:

- Steel casting:

- Brass casting:

- Ductile iron casting:

- Zinc casting:

Common aluminium alloy used in aluminum casting: A356, ZL101, 6061.

Aluminum is a lightweight, strong, and corrosion-resistant material that is widely used in modern industry. It is typically used in gravity casting, sand casting, low-pressure casting, and die casting. This makes aluminum one of the most widely used materials in modern industry. It is widely used in automotive, aerospace, and other industries. It is also used in a variety of consumer goods, such as electrical appliance supports and the legs of office chairs.

Yontone is a casting foundry that can provide aluminum casting services for a variety of products, including engine components, structural parts, and consumer goods.

Common iron casting material: HT100, HT150, HT200, HT250, HT300, HT350

Iron is heavier than other metals, but it is a strong and durable material. It is also less expensive than ductile iron and steel. This makes cast iron products widely used in industry and life.

It is used in a wide variety of applications, including: home cookware, stews, soups, and other dishes; construction, beams, columns, and pipes; machinery, gears, bearings, and engine blocks; transportation, car frames, truck axles, and train wheels.

Yontone is a casting manufacturer that can provide iron casting services for a variety of products, including castings, forgings, and machine parts.

Steel is an alloy of iron and carbon. The carbon content in steel determines its properties. Low-carbon steel is soft and ductile, while high-carbon steel is hard and strong.

Steel is a strong and versatile material that is used in a wide variety of applications. It is stronger than iron, and it has better machinability and weldability. Commonly used cast steel materials include: Q235 (low-carbon steel), C45 (medium-carbon steel), ZG42CrMo (high-carbon, high-chromium steel)

Yontone is a casting supplier who provides steel casting services for a variety of products, including engine components, structural parts, and machine parts.

Brass casting is a common manufacturing process widely used in aerospace, automotive, machinery, electronics, and other fields. Cast brass alloys have strong corrosion resistance in different environments. In some application scenarios, like chemical equipment, marine engineering, and other fields that require high corrosion resistance, it is necessary to choose cast brass alloys with better corrosion resistance.

Lead-free brass is widely used in medical equipment components, IT communication components, cable TV components, electronic and electrical connectors, connectors, screws, water purification equipment components, valves, hardware, clothing, zippers, and other industries.

Yontone is a casting company who provides high-quality brass casting services & high-end lead-free brass casting that comply with the requirements of ROHS and WEEE directives.

Commonly used cast ductile iron materials include::QT400, QT450, QT500, QT600

Ductile iron is a strong and tough material, compare with iron, dutile iron is more impact-resistant, corrosion-resistant, heavier, and stronger, but it’s harder to be machined. Its price is lower than steel. Because it has the advantages of ordinary cast iron and steel, it has become a new structural material.

It is used in a variety of applications, including automotive, construction, and machinery, such as crankshafts, connecting rods, spindles, medium-pressure valves, etc.

Yontone provides clients with ductile iron casting services for a variety of products, including engine components, structural parts, and machine parts.

Zinc alloys have the following properties: non-magnetic, low melting point, good fluidity, corrosion resistance, good machinability, and good surface finish.

These properties make zinc alloys a versatile material that can be used in a wide variety of applications. Zinc alloy castings are often used to make: hardware, knobs, hinges, and handles; automotive applications, engine components, brake components, and exterior trim; appliances, washing machines, dryers, and refrigerators; electrical components, connectors, switches, and housings; decorative components, ornaments, and lighting fixtures.

Yontone provides high-quality zinc casting services with cost-effective solutions for a variety of products, including engine components, structural parts, and consumer goods.

The Current Application of Casting Products

Casting solution is a relatively economical blank-forming method, and it can show its economy more for parts with complex shapes. Such as the cylinder block of automobile engines, cylinder heads, ship propellers, and exquisite artwork.

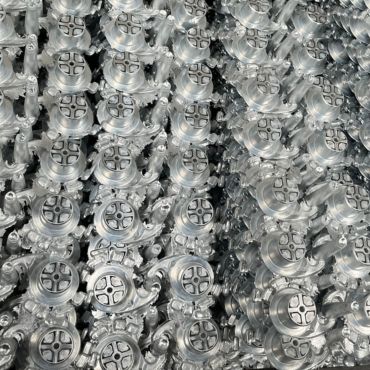

Below are products once produced by Yontone, just for your reference. We can do a lot more.

Advantages of Casting Process

Steel, iron, stainless steel, aluminum alloy, zinc alloy, brass alloy, titanium alloy, tin, and lead can all be melted and cast.

With the collaboration of sand cores, casting molds can create parts with internal structures more intricate than those achievable through die-casting.

Capable of manufacturing items spanning from a few grams to several hundred tons, and proficient in crafting products with wall thicknesses varying from 0.1 to 1 meter.

Compared with die-casting molds, casting molds are much cheaper. Suitable for small batch production or prototype.

Key Factors in Ensuring Quality Castings

Casting is a complex manufacturing process, and to ensure the production of high-quality, defect-free castings, we need to rigorously control the following key factors: temperature, pouring speed, pouring pressure, cooling rate, sand mold, and mold preparation, material composition, coating, as well as documentation and inspection.

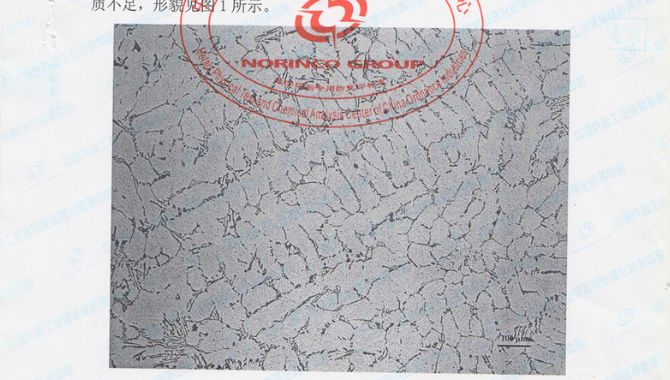

Metallographic Test

Yontone utilizes metallographic testing to assess the excellence, composition, and effectiveness of metal and alloy materials post-casting. This analysis includes elements like grain dimensions, phase allocation, width ratios, and the identification of structural irregularities or variations.

Quality Control

Quality inspection for castings includes visual inspection, dimension measurement, material composition analysis, mechanical performance testing, and more. Yontone follows strict procedures for inspection, documentation, and determining qualified products eligible for shipment.

Why Opt for Yontone as Your Casting Supplier

Yontone, who has been in the foundry and processing industry for decades, is very familiar with the advantages and disadvantages of various castings and applicable products. According to the customer’s order quantity, product structure, surface treatment and subsequent machining requirements, we will provide customers with reasonable casting and processing solutions. And provide surface treatment to help customers complete all intermediate production processes from drawings to products.

1. Yontone has a team with more than 8 years of professional experience in casting mold design. For any kind of casting, excellent mold design is the foundation. Good mold design can help improve production efficiency, reduce material waste, increase yield and reduce scrap.

2. Yontone’s production workers all have more than 10 years of experience in casting production. Using the same mold, they can produce higher quality products.

3. Wide production line, can produce brass casting, aluminum alloy casting, iron casting, ductile iron casting, steel casting products. It can meet more than 90% of customers’ needs for materials.

4. Yontone can provide casting products after machining, and customers can directly assemble and assemble them.

5. The quality inspection report is complete. According to the needs of customers, we can provide material reports, metallographic inspection reports, CMM full-scale reports, tensile test reports, surface treatment bonding force tests, hundred grid tests, salt spray tests, etc.

6. Prompt delivery. Because the production progress is reported to the customer every week, the customer is very clear about the production status of the order. Unless encountering force majeure, each order of Yontone is delivered on time or even ahead of schedule.

7. High cost performance. Yontone wants to make affordable and high-quality products. Cost-effective products can help customers open up and occupy the market. We want to grow together with customers.

Yontone’s vision is to do a good job in the first link of industrial manufacturing, to provide customers with high-quality, long-life and low-price industrial parts, and to be a high-quality supplier. We hope this business can last for a hundred years.

Wild Application Fields of Casting Process

Casting parts are widely used in people’s production and life. In general machinery, castings account for about 40-90% of the total weight of the machine, more than 40-70% in agricultural machinery, and 70%-80% in metal cutting machine tools.

Applications of casting products in the auto parts industry:

- engine parts, cylinder blocks, cylinder heads, crankshafts, pistons, connecting rods and other components;

- casting components, suspension parts, brake calipers, steering gear housings;

- exhaust systems, exhaust manifolds, mufflers, and tailpipes;

- wheel hubs and brake discs; oil and water pumps;

- electronic component housings, control units (ECUs), and sensor housings.

Yontone provides automotive manufacturers with high-strength, practical, and cost-effective casting product solutions.

Casting products have a wide range of applications in the construction industry, involving the manufacturing of various building structures and infrastructure. Here are some common applications of casting products in the construction industry:

- structural components, manufacturing load-bearing elements such as beams, columns, and crossbeams;

- bridge components, structural parts like bridge piers, abutments, beams, and connectors; components for drainage systems, such as rainwater inlets, inspection manhole covers, and sewage pipes;

- the field of architectural decoration, producing decorative elements like railings, patterns, and sculptures; foundation infrastructure, including components for foundation engineering such as piles, underground support structures, and other foundation elements;

- protective equipment, such as explosion-proof doors and fire doors.

Yontone’s produced metal casting products provide customized, durable, and high-strength solutions in the construction industry, supporting the safe, reliable, and aesthetically pleasing construction of buildings.

The application of casting products in the energy industry is highly diverse, encompassing the extraction and utilization of traditional energy, power generation from renewable sources, and emerging energy technologies. Here are common applications of casting products in these fields:

- Petroleum Drilling Equipment Components: like drill bits, downhole tools, and pump bodies.

- Oil and Gas Pipeline Components: Including pipeline connectors, flanges, and valves.

- Components for Nuclear Reactors: Such as reactor vessels and cooling system parts.

- Components for Wind Turbines: Including wind blades, hubs, and bearing seats.

- Support Structures for Solar Panels: Involving support structures and fixed components.

- Components for Hydroelectric Generators: Such as turbine blades, bearings, and generator casings.

- Equipment for Substations: Such as transformer casings and circuit breaker housings.

- Battery Casings and Heat Dissipators: Used in electric vehicles and energy storage systems.

- Components for Hydrogen Fuel Cells: Including stack cores and reactor casings.

In summary, casting products manufactured by Yontone provide critical support for the development and operation of the energy industry by offering high strength, intricate shapes, and corrosion resistance. Their applications span the entire energy spectrum, from traditional to renewable sources and cutting-edge technologies.

Casting products have extensive applications in agricultural machinery, providing durable and high-strength components to meet the diverse and critical needs of agricultural equipment. Here are some common applications of casting products in agricultural machinery:

- Tractor Components: Engine cylinder blocks, crankshafts, and engine hoods.

- Harvester Components: Blades, cutting disc blades, and machine casings.

- Seeder Components: Planting units, seed discs, and seed wheels.

- Irrigation Equipment Components: Valves, pipe connectors, and pump bodies that are corrosion-resistant and stable.

- Farm Vehicle Components: Wheels, suspension components, and certain components in the braking system.

- Power Machinery Components: Key components of diesel engines, such as cylinder heads, cylinder blocks, and crankshafts.

- Structural Components for Agricultural Equipment: Frames, supports, and protective covers.

The casting components produced by Yontone, when used in agricultural machinery, enable manufacturers to achieve cost-effectiveness, large-scale production, and the manufacturing of complex-shaped parts. This ensures the reliability of agricultural machinery under harsh environmental conditions and heavy loads.

The application of casting products in the medical field is highly extensive, involving various aspects such as medical equipment, surgical tools, and diagnostic devices. Here are some common applications of casting products in the medical field:

- Medical Equipment Components: Housings, supports, and critical structural components for X-ray machines, CT scanners, MRI machines, etc.

- Various Surgical Instruments Used in Operating Rooms: Handles for surgical knives, surgical clamps, and orthopedic implants.

- Artificial Hip Joints, Artificial Knee Joints, and Other Implants.

- Dental Instruments: Components for dental chairs, dental bridges, and other dental equipment.

- Housings for Medical Devices: Housings for monitors, respirators, and other medical devices.

- Components for Diagnostic Equipment: Components for blood analyzers, biochemical analyzers, including sample containers and analysis chambers.

- Medical Assistive Devices: Components for wheelchairs, walkers, hospital beds, and other medical assistive devices.

By applying casting products in the medical field, Yontone casting can provide highly customized components that meet medical standards, ensuring the necessary strength, durability, and biocompatibility. These products play a crucial role in promoting innovation in medical equipment and improving the overall level of medical services.

Casting has extensive applications in the railway transportation industry, involving the manufacturing of trains, tracks, and other railway equipment.

Here are some common applications of casting in the railway transportation industry: Train Wheels; Track Components: Rail joints, track fishplates, and track fasteners; Braking System Components: Brake calipers, brake discs; Train Body Structure: Frame, body supports, etc.; Railway Signal System Components: Supports, signal equipment housings, etc.; Electrical Connection Components: Electrical connector housings, cable conduits, etc.; Rail Vehicle Components: Bogies, footplates, etc.; Railway Bridge Components: Bridge bearings, bridge connectors, etc. These applications showcase the diversity of casting technology in the railway transportation industry.

Yontone casting provides high-strength, intricately shaped components for railway systems, offering both cost-effectiveness and the ability for large-scale production. This contributes to ensuring the safety, reliability, and efficient operation of railway systems.