What is CNC turning?

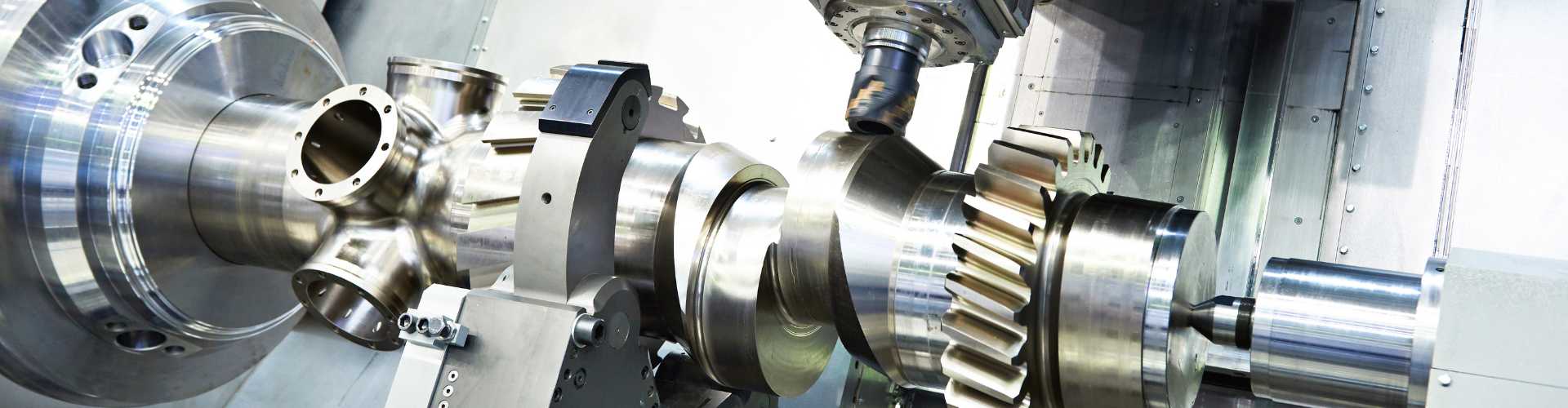

CNC turning is a machining process usually performed on a CNC turning center or CNC lathe, also known as CNC lathe machining.

In this process, the spindle rotates at high speed to drive the raw material or casting. A turning tool mounted on a tool holder is formed to produce a variety of features on a typically round workpiece.

These functions include turning faces, internal and external diameters, arcs, tapers, boring, eccentricity, embossing, cutting, grooving and threading.

CNC turning consists of CNC (computer numerical control) + turning.

- “CNC” refers to a computer-controlled program that uses tools or parts to move.

- “Turning” refers to the process of rotating (turning) materials or castings.

CNC turning parts find extensive applications across various industries because of their ability to precisely manufacture a wide range of complex components, meeting the diverse needs of different sectors. These include automotive engine components, flight control systems, medical equipment parts, electronic device components, gas turbine components, wind turbine parts, pumps, valves, bearings, marine propulsion system components, door and window accessories, and more.

CNC Turning Parts with Different Materials

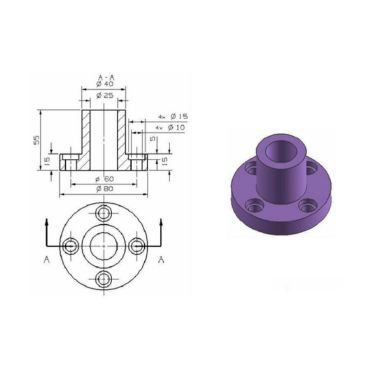

Based on the customer’s specific projects and drawings, we offer both large-scale CNC turning services and small lathe products, with sizes ranging from a maximum of 440mm to a minimum of 2mm (mini lathe parts).

Our CNC-turning products are widely praised and highly regarded by our customers. Materials that can be CNC turned:

- Different metal alloys: aluminum alloy, steel plate, copper, steel, iron, zinc alloy, titanium alloy, magnesium alloy;

- Different plastic materials: POM rod. PE sheet, PEEK, PA, PUE, PTFE, standard, ABS, PP, bakelite;

- Different wood materials: walnut, oak, maple, pine, cherry, beech, cherry, ash, eucalyptus

Please send 2D and 3D drawings to get an online quote. Contact your premier turning service provider today!

We use high quality and durable extruded aluminum alloy to manufacture aluminum turned parts.

- Surface treatment: Color anodizing (red, yellow, blue, purple).

- Processing process: CNC turning, milling

- Material grade: 6061-T6511-extrusion, 2024 T351, 7075 T651 alloy, etc.

We use high-quality brass rods or solid blocks to manufacture brass turned parts.

- Surface treatment: ultrasonic cleaning, polishing, passivation, chrome plating.

- Processing process: CNC turning and milling

- Material grade: H59, H62, etc.

We use high quality steel blocks, tubes, rods to manufacture iron and steel turned parts.

- Surface treatment: blackened, powder sprayed.

- Processing process: CNC turning and milling

- Material grades: C45, C20, A3, cast iron, cast steel, etc.

We use high quality zinc rods or zinc alloy die castings to manufacture zinc turned parts.

- Surface treatment: nickel plating, chrome plating.

- Processing process: CNC turning and milling

- Material grades: zinc alloy 3, zinc alloy 5, zinc rod 0#, 2#, 3#, 5#, etc.

We use high-quality titanium plates and titanium blocks to manufacture titanium turned parts.

- Surface treatment: Polishing and colorful PVD coating.

- Machining process: CNC turning and milling

- Material grade: Ti-6Al-4V (grades 5, 24),Ti-5Al-2.5Sn (grade 6), etc.

We use high-quality plastic block, or plastic injection parts to make plastic turned parts.

- Surface treatment:

- Machining process: CNC turning and milling

- Material grade: PC, PE, PA, ABS, bakelite, etc.

The Order Process for CNC Turning Order Parts

Drawings, quotations, design tooling, design production process, delivery of samples, delivery of bulk goods

Advantages of Yontone CNC Turning

Yontone’s CNC turning processes offer exceptional precision, ensuring that the final products meet tight tolerances and specifications. CNC lathe machining: Simple tooling, high machining precision, easy to program.

Yontone’s use of high-precision CNC turning center features excellent concentricity as holes, outer circles, and inner circles are machined in a single operation. It also ensures the consistency of various dimensions.

To support small business starters, Yontone’s custom turning service requires low MOQ. Small business owners can invest smaller amounts of money to start.

Compared to machining centers, CNC lathes machining services have lower demands on the skill level of operators, and their high level of automation leads to lower unit prices for products.

CNC Turning Fixtures Design and Manufacturing

Yontone has a dedicated precision engineers team who design fixtures that tailor efficient fixtures for each lathe product.

These fixtures are designed to ensure both product machining precision and enhanced production efficiency.

Advanced Equipment

The utilization of advanced CNC milling and turning machines, including CNC turning centers and lathing machines, has substantially increased production efficiency. This improvement in efficiency has been achieved without compromising our unwavering commitment to quality, resulting in cost reductions that benefit our customers.

Quality Control

- Incoming Material Inspection: All materials must arrive with material reports, and our warehouse conducts inspections on receipt.

- In-Process Checks: Our machinists perform self-checks throughout production, addressing issues promptly.

- Spot-Checks: Our QC team conducts regular spot-checks during production for added assurance.

- Final Inspection: Before shipping, products undergo comprehensive inspections for size, mechanical performance, and air-tightness.

- Transparency through Video: We provide CNC turning videos for visual inspection.

- Detailed Inspection Reports: We maintain comprehensive inspection reports for complete traceability.

With each step, we prioritize precision and quality, ensuring excellence in CNC turning.

Selecting Yontone as Your CNC Turning Supplier: Why It's the Right Choice

At Yontone, we prioritize delivering exceptional value to our clients. With over 15 years of expertise in CNC turning and machining, we stand out in several crucial aspects.

- 1. Quality-Driven CNC Turning Services: Our focus is on exceeding your expectations. As a leading CNC turning company, we offer a range of services, including online CNC turning and milling turning services. Our CNC lathe machining expertise guarantees precision, and advanced quality and size-checking equipment ensures top-notch results.

- 2. Expert Engineering Team: We understand that your success hinges on quality and innovation. That’s why our precision engineers team of dedicated engineers boasts a minimum of 8 years of experience in fixture, cutter, and tooling design. They work tirelessly to enhance the value we bring to your projects.

- 3. On-Time Delivery: Your deadlines are our commitment. We have a proven track record of timely delivery. When you choose Yontone as your CNC turning manufacturer, you can trust us to meet your schedules reliably.

- 4. Flexible MOQ and Competitive Pricing: As your CNC turning company, we aim to cater to your specific needs. We offer a low Minimum Order Quantity (MOQ), allowing you to align our services with your project’s scale. Our competitive pricing ensures you receive exceptional value for your investment.

- 5. Online Quoting and Service: We know that modern businesses operate at a fast pace. That’s why we provide convenient online quotes and online CNC turning services. This seamless, digital approach allows you to access our expertise at your convenience. We can even send online CNC turning videos to support your understanding of our processes.

What’s more? Our one-stop solution, derived from extensive experience in casting and die-casting, covers everything from materials to finished products for our valued customers. We are well-versed in working with various materials, including aluminum, zinc, brass, iron, steel, wood, plastic, and rubber.

Wild Application Fields of CNC Machining Parts

High precision and reliability are key elements in the manufacturing of automotive parts, and CNC turning can provide precision machining to ensure that parts meet stringent specifications.

Yontone’s steel CNC-turned parts are widely used in the automotive manufacturing industry, including engine parts, brake system components, and steering system components.

The aerospace industry has very high requirements for the precision and lightweight of parts.

Yontone’s aluminum CNC turning products can achieve high-precision machining of complex parts and is widely used in the manufacture of aircraft engine components and aerospace components.

In the electronic manufacturing field, parts usually require high precision and complex geometric shapes.

Yontone manufactures various components such as connectors, sockets, and electronic device housings through CNC turning.

Energy industry components typically require high strength and wear resistance.

Yontone’s CNC turning parts is used to manufacture key components in the energy industry, such as turbine components and generator parts.

In the medical field, high precision and reliability are essential.

Yontone’s CNC turning components play an important role in the manufacturing of medical device components, including artificial joints, surgical tools, and medical instruments.