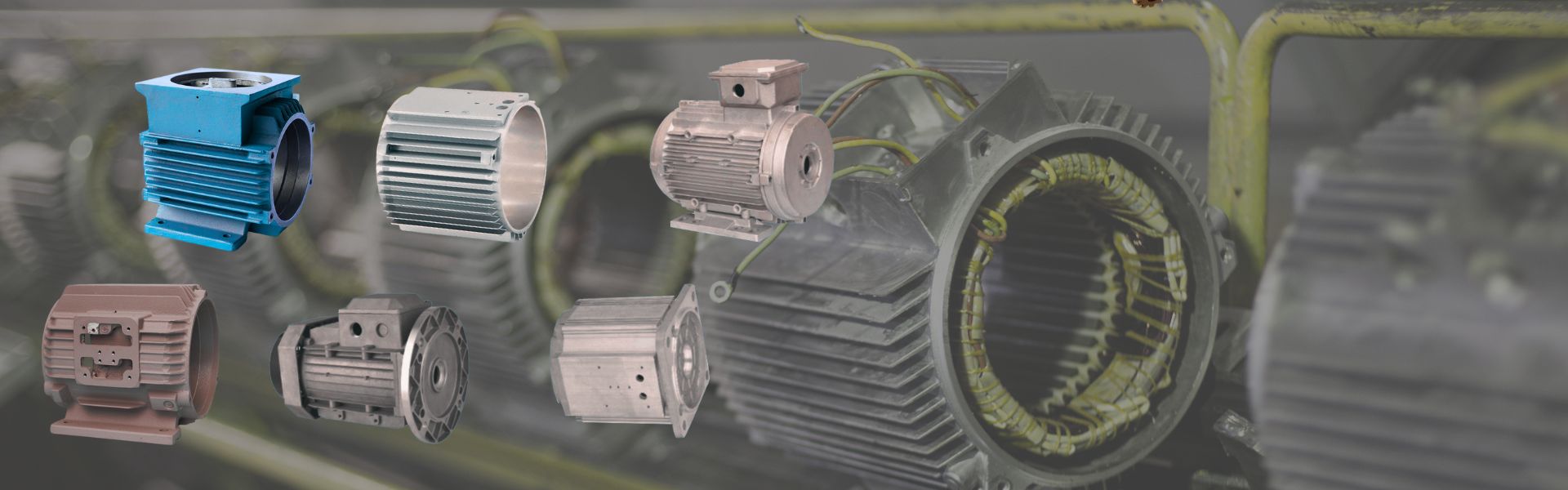

Motor Housing Meaning

- What is a motor housing?

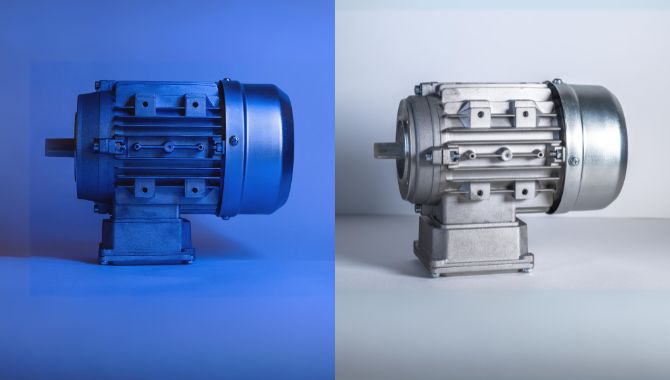

The motor housing serves as an external cover for the motor, not only playing a crucial protective role in preventing external forces from causing damage to internal motor components, but also acting as a mounting frame for motor components.

A good motor casing should balance practicality, durability, and cost-effectiveness. Selecting the appropriate material and size for the motor casing is crucial depending on the usage environment and application field.

- The services Yontone provides for customized aluminum motor housing.

- Die casting mould making

- Die casting parts manufacturer

- Motor housing with CNC machining Service

- Motor housing with surface treatment

These services can be provided individually or as a comprehensive package.

- What is the function of the Motor Housing?

Its primary function is to shield internal components like the rotor, stator, and windings from potential damage caused by dust, moisture, chemicals, or external forces.

Effective heat dissipation is facilitated by the design of heat-dissipating ribs on the motor casing, preventing overheating during motor operation. This ensures the motor remains within an optimal temperature range, safeguarding its original components from damage.

As the motor operates, it carries an electric charge. A motor shell acts as a barrier, preventing operators from direct contact with the charged interior and minimizing the risk of electric shock accidents.

Motor housing designs can be tailored to meet specific waterproof requirements, utilizing different protection levels such as IP65 or IP66.

- Motor Housing Types

Electric motor housing types are categorized based on their power sources into AC motor housings and DC motor housings. DC motor housings are further divided into brushed DC motor housings, brushless DC motor housings, and hollow-cup DC motor casings. AC motor casings are classified into synchronous motor casings and asynchronous motor bodies.

Others like AC motor housings & EV motor housings are quite popular these days.

- Motor Housing HS Code

Customs codes for motor casings and motor housing covers vary slightly depending on the final use of the product.

For other kinds of motors and motor (set) parts,” you may choose customs code: 85030090.90.

Alternatively, based on the material of the product, such as aluminum profile motor housings, you can select customs code: 76042990.

For aluminum die-cast motor housings, you may choose customs code: 76169910.90. Please note that customs codes may vary slightly between countries.

What are the different types of motor housing materials commonly used in the industry?

The choice of material for motor casings has a significant impact on motor performance. Materials such as cast iron, cast steel, stainless steel, or aluminum alloy are selected based on factors such as motor size and strength requirements. Larger motor housings may utilize cast iron or cast steel, while smaller to medium-sized ones commonly opt for aluminum alloy. To save costs, small-capacity motors and those used in household appliances, like electric fan motor housings, may also utilize plastic motor casings.

While motor housings protect the motor, they also play roles in heat dissipation and sound insulation. Cast iron housings offer high hardness, while aluminum die-cast housings are lightweight, have good thermal conductivity, and exhibit strong malleability. They can be cast or extruded, with stable elongation properties and superior sound insulation compared to iron.

Yontone can customize aluminum alloy die-cast motor casing covers and aluminum alloy profile motor casing covers to enhance motor rigidity and shock resistance.

Aluminum is the most widely used material for motor housings. Aluminum motor housings can be produced through aluminum die casting, resulting in motor casings with versatile shapes. Moreover, aluminum alloys are easy to machine, with high machining accuracy.

Zinc alloy die-cast motor housings possess excellent conductivity and heat dissipation properties, as well as resistance to corrosion from seawater, making them suitable for motor housings in humid environments. Die-casting molds for zinc alloys are cost-effective and efficient, making them suitable for producing small motor casings.

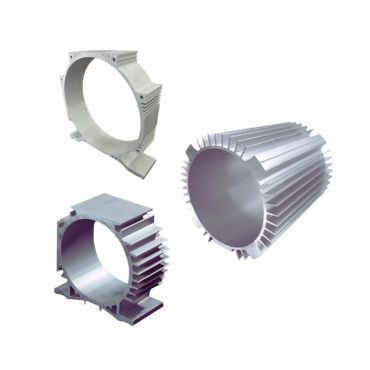

Aluminum extrusion electric motor housings offer excellent heat dissipation, ease of processing, low mold prices, and affordable casing prices. They are a highly cost-effective housing option.

Due to the nature of extrusions, they maintain consistent shapes and cannot accommodate irregular forms.

Producing motor housings with precise dimensions and accuracy through aluminum machining is typically suitable for customizing small-batch motor housings.

Iron has high hardness, great strength, and significant mass, making it an ideal choice for large-scale motor housings. Typically, iron motor housings are produced through sand casting or lost wax casting, with relatively inexpensive mold prices.

Steel stamped motor housings, produced through steel plate deep drawing, feature inexpensive molds, high efficiency, low unit costs, and lightweight design, making them the preferred choice for micro motor housings.

How are different types of motor housings manufactured?

Based on design requirements, considering factors such as motor housing dimensions, pressure resistance, working environment, and product pricing, the initial step involves selecting the material for the motor housing. Subsequently, an appropriate manufacturing process is chosen, such as injection molding, die-casting, casting, deep drawing, or sheet metal processing.

The electric motor housing manufacturing process needs to consider both material properties and the complexity of the process, adopting suitable procedures to ensure product quality and performance.

Here is a comparison of various production processes and different materials for motor casings:

| Material | Production Process | Advantages | Disadvantages |

|---|---|---|---|

| Aluminum Alloy | Die Casting | Lightweight, Good Strength, Excellent Heat Dissipation, Aesthetic | Expensive Die Casting Molds |

| Aluminum Alloy | Aluminum Extrusion, Profile | Lightweight, Good Strength, Excellent Heat Dissipation, Aesthetic | Only for Regular Shapes |

| Iron | Foundry, Sand Casting | High Strength, Inexpensive Molds | Heavyweight, Moderate Heat Dissipation |

| Steel Plate | Stamping, Deep Drawing, Welding | Lightweight | Poor Heat Dissipation, Low Strength, Unsuitable for Large Motor Casings |

| Plastic | Injection Molding | Lightweight, Inexpensive | Poor Heat Dissipation, Low Strength, Unsuitable for Large Motor Casings |

How to Make Aluminum Die Casting Motor Housings?

Different Types of Die Casting Motor Housings

Here’s a table summarizing the application areas of aluminum motor housings:

| Application Area | Examples |

|---|---|

| Automotive Industry | Electric vehicles, hybrid vehicles, automotive components |

| Industrial Machinery | Pumps, fans, compressors, conveyors, industrial equipment |

| Home Appliances | Washing machines, refrigerators, air conditioners, kitchen appliances |

| Aerospace and Defense | Aircraft, spacecraft, military vehicles, defense systems |

| Renewable Energy | Wind turbines, hydroelectric generators, solar power systems |

| Marine and Offshore | Ship propulsion systems, offshore drilling rigs, marine equipment |

| Medical Devices | Medical imaging devices, laboratory equipment, surgical tools |

| Consumer Electronics | Computers, printers, scanners, consumer electronic devices |

| Agricultural Machinery | Tractors, harvesters, irrigation systems, agricultural equipment |

| Construction Equipment | Excavators, cranes, bulldozers, construction machinery |

Each application area utilizes motor housings for various types of machinery and equipment.

Advantages of Aluminum Die Casting Motor Housing

Aluminum offers a lightweight solution, making it suitable for weight-sensitive applications.

Aluminum’s high thermal conductivity ensures efficient heat dissipation, enhancing motor performance and durability.

Aluminum motor housings are resistant to corrosion, increasing their longevity, especially in harsh environments.

Aluminum’s molding versatility, combined with its eco-friendly nature, provides design flexibility, energy efficiency, and long-term sustainability.

Customized Aluminum Die Casting Motor Housings Supplier

Considering both economic factors and durability, an aluminum motor casing is the optimal choice.

YONTONE specializes in producing a variety of electric motor housing molds and customized motor housings for motor manufacturers.

As a professional aluminum die-casting motor casing manufacturer, Yontone delivers high-quality motor casings that are sturdy, durable, and competitively priced. With precision engineering, our motor housings demonstrate high accuracy and strength, contributing to the extended lifespan of electric motors.

We provide customers with a comprehensive one-stop service from mold design and die-casting to machining and surface spraying, ensuring seamless production from initial drawings to finished products.

Surface Treatment

The surface of the aluminum die casting motor housing is typically treated with powder coating. The advantages of powder coating include a wide range of colors, a thicker coating compared to paint, cost-effectiveness, aesthetic appeal, and resistance to corrosion, rust, and mold.

Quality Control

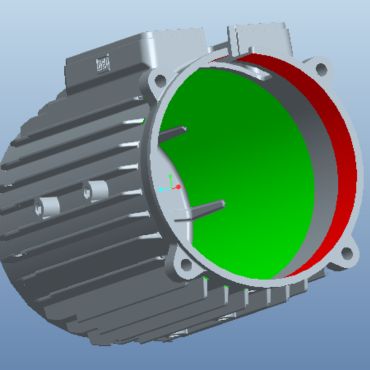

The motor housing not only requires precision in die casting to control the accuracy of its external shape through mold dimensions but also needs machining to control the assembly dimensions of the bearing holes, main holes, and end cap mounting holes inside the motor housing. Yontone will use CMM to test the concentricity of several holes on the same axis.

Packing and Delivery

Yontone will calculate suitable pallet dimensions based on the size of the motor housing and the internal dimensions of the container. Additionally, Yontone aims to maximize product loading within the container to help reduce transportation costs for the customer. Typically, small motor housings are packed in cardboard boxes before being palletized, while large motor housings are directly packed in wooden crates. Finally, the pallet will be wrapped in plastic film to protect it from moisture during shipping.

Motor housings can de delivered by express, by air, by sea, by train.

Wild Application Fields of Customized Aluminum Die Casting Motor Housings

In electric vehicles, the electric drive motor is one of the three core components. It serves as the primary executive structure in the operation of electric vehicles, converting electrical energy from the power source into mechanical energy to drive the vehicle through a gearbox or direct drive system. Aluminum motor housings contribute to overall vehicle weight reduction, enhance motor heat dissipation, and the mass production efficiency of aluminum die-casting meets the demands of large-scale production for electric cars, buses, trucks, and other vehicles.

These motor housings are places onboard ships where explosive atmospheres may be formed by flammable gases, vapors, and air, classified as Groups IIA, IIB, and IIC, with temperature classes ranging from T1 to T4. They are used to drive various machinery onboard ships, such as pumps, fans, separators, hydraulic machinery, and other auxiliary equipment.

The lifting principle of metallurgical overhead cranes relies on the motor’s rotor driving the gearbox, which in turn activates the lifting mechanism. The lifting mechanism consists of a drum, wire ropes, and a lifting hook. When the motor starts operating, the drum begins to rotate, causing the wire ropes to stretch and subsequently lifting the load through the lifting hook.

The doubly-fed asynchronous wind turbine generator is a core component of variable speed constant frequency wind turbines. It is also one of the key components for localizing wind turbine generators. The generator mainly consists of the motor body and cooling system. The motor body comprises the stator, rotor, and bearing system. The cooling system is divided into water-cooled air cooling and air-water cooling.

The motors housing used in the food and beverage industry typically need to meet very stringent requirements. They are employed in processes such as grinding, mixing, and conveying in the processing of meat, poultry, fish, dairy products, and baked goods. Moreover, equipment used in food and beverage processing must operate flawlessly throughout their entire lifecycle, run for long periods, and exhibit extremely high levels of energy efficiency.

The design of mining use motor housing must adhere to stringent requirements to ensure safe operation in explosive environments. Key design considerations include:

Material Selection: The housing material needs to possess characteristics such as impact resistance, corrosion resistance, good thermal conductivity, and anti-static properties. Common materials include aluminum alloys, cast iron, cast steel, and engineering plastics. Material selection should also consider production costs and availability.

Explosion Resistance: The housing must withstand the pressure generated by internal explosions without rupturing or undergoing permanent deformation. Choosing appropriate materials and wall thickness is crucial to ensure the housing has sufficient strength and rigidity.

The motor is suitable for voltage-source type inverter systems for driving and controlling. It can be used to drive drilling rig winches, mud pumps, turntables, etc., and can also be used as the drive motor for other variable frequency speed control devices.