Why Should We Choose Aluminum CNC Machining Parts?

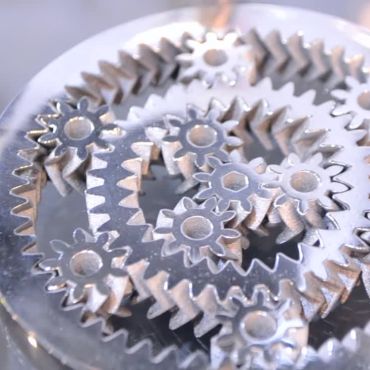

- Aluminum alloy is composed of aluminum, copper, magnesium, manganese, zinc and other elements. It is lighter and more corrosion-resistant than steel and iron. · It has better thermal and electrical conductivity. · It is more malleable and easy to be machined. Therefore, spare parts, steel parts, and iron parts in many industrial fields are gradually replaced by lightweight CNC Aluminum parts.

- Compared with aluminum alloy casting parts and aluminum die-casting products, machined aluminum parts have higher precision. Hydraulic parts, industrial parts, and auto parts all have assembly accuracy and sealing requirements. The final product must be machined to ensure its assembly size and accuracy.

Aluminum CNC Machining Combines with Other Processes

Aluminum parts manufacturing can directly use billet aluminum materials. Or make a rough product through production processes such as aluminum die-casting, aluminum casting, aluminum extrusion, or aluminum forging, and then machining the parts. This will create complex shapes and accurate assembly sizes, and also be very cost-effective.

Yontone as an aluminum CNC machining company provides customers with one-stop aluminum parts manufacturing services, from molds, casting, die-casting to machining and surface treatment.

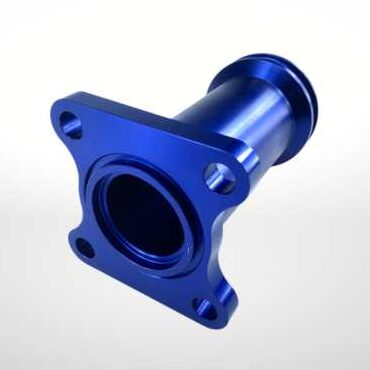

Yontone manufactures Custom Billet Aluminum Parts for customers. The most commonly used machined aluminum materials and are machined directly on aluminum blocks or rods. The aluminum parts after CNC machining of aluminum billet can be spray-painted, plastic-coated, electrophoresed, but also made into metallic colors through anodization.

Aluminum parts machined after die casting are more cost-effective compared to those made entirely through machining. They also retain the excellent assembly performance of fully machined products. For surface treatments such as painting, powder coating, or electrophoresis are typically applied. Many components assembled within machine systems do not require additional surface treatment.

Like aluminum sand casting products, aluminum low-pressure casting products, and aluminum gravity casting products, casting parts have low dimensional accuracy. Yontone factory will post-process the casting parts because aluminum alloy CNC machining must be performed to ensure assembly dimensions.

Custom CNC Aluminum

Yontone is a custom aluminum manufacturing factory, who provides different kinds of online CNC aluminum machining services: custom aluminum milling, cnc aluminum turning, cnc aluminum cutting, aluminum prototype machining, aluminum additive manufacturing, aluminum 3d printing service, aluminum CNC drilling, aluminum CNC engraving, aluminium CNC grinding.

Yontone is equipped with world-class 3-axis and 4-axis machining centers, providing custom aluminum CNC machining services, including milling aluminum using a router, an aluminum milling machine, or a machining center. Customers can send an inquiry online, and get quotation in 2days. s

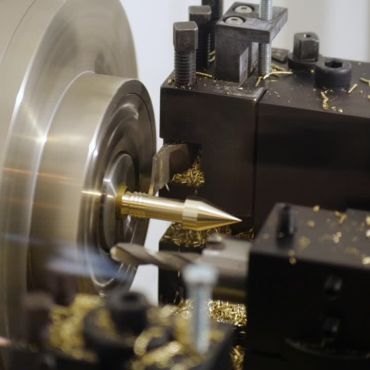

The CNC aluminum turning process involves machining aluminum on a lathe. The custom aluminum pieces are fixed on the fixture and will keep turning during the cutting process.

Yontone is equipped with CNC lathes of various sizes to customize high-precision aluminum alloy products for our customers.

Based on different product requirements, Yontone provides various aluminum cutting services, including wire EDM cutting, aluminum laser cutting, and waterjet cutting. Each cutting method offers different levels of dimensional accuracy. Whether it is fast wire EDM or slow wire EDM, the surface finish and precision are superior to those of laser cutting machines.

Besides large-volume aluminum CNC machining parts, Yontone also provides small-volume aluminum CNC machining services, which is we often call CNC Aluminum Prototype. This type of custom-made aluminum part is usually used to verify product designs before customizing molds for mass production. CNC Aluminum Prototype is used to verify the effect of assembly, accuracy and strength in operating in actual systems.

DMLS Direct Metal Laser Sintering,AlSi10Mg or 6061 aluminum billet material can be used to 3D print aluminum parts, enabling the production of hollow and curved structures that are difficult or costly to achieve with CNC aluminum machining.

Yontone uses CNC precision automatic lathes to machine small aluminum cnc parts. The automatic lathe has high efficiency and high precision. Compared with ordinary machining centers for processing small aluminum parts, it can reduce a lot of costs.

More Aluminum CNC Machining Parts

Yontone is an OEM company with 16 years of experience producing aluminum CNC machining. Our products are primarily used in automotive parts, aerospace, hydraulic systems, power tools, lighting, new energy, and furniture industries. You can send us 3D and 2D drawings for a quotation. We accept both large and small-batch orders.

Why Choose Yontone as Your Supplier for Aluminum CNC Machined Products?

- Yontone has 16 years of experience in aluminum alloy CNC machining. All fixtures and toolings are designed by our in-house designers, which will maximize clamping and machining efficiency. We design and customize specialized PCB-integrated forming cutters to ensure product concentricity and precision. While meeting the high precision requirements of the product, we strive to minimize aluminum machining costs.

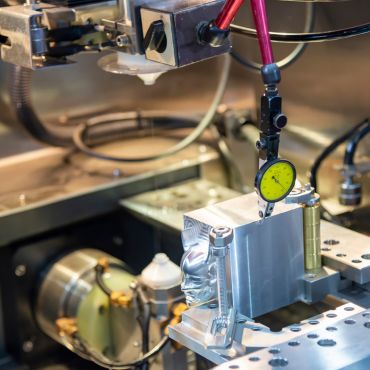

- At Yontone, every critical dimension of aluminum machining products is fully inspected by operators directly at the machine. Dedicated inspectors conduct hourly patrol inspections. Upon completion of the entire order, quality inspectors perform sampling inspections according to the order quantity. We provide a material report and a full-size inspection report with every shipment.

- We place great importance on delivery timelines. A dedicated team plans production schedules, and Yontone offers real-time video and telephone meetings, allowing customers to monitor order progress every week. Each order is delivered with guaranteed quality and on schedule.

Billet aluminum is formed by forging or extrusion.

Most common billet aluminum material used in China are 6061 T6, 7075 T6, and 2024 T4. Other CNC aluminum alloys are below.

| Alloy Name | Standard Designation | Temper | Composition | Key Properties | Applications |

| Aluminum 6061-T6 | 3.3211 | T6 | AlMg1SiCu | Good strength-to-weight ratio, excellent machinability, natural corrosion resistance |

General purpose, structural components, aerospace, automotive

|

| Aluminum 7075-T6 | 3.4365 | T6 | AlZn5,5MgCu | Excellent strength-to-weight ratio, high strength and hardness |

Aerospace, military, high-stress applications

|

| Aluminum 6060 | 3.3206 | – | AlMgSi | Good strength, relatively good corrosion resistance, suitable for decorative anodizing |

Architectural applications, extrusion profiles

|

| Aluminum 6082 | 3.2315 | – | AlSi1MgMn | Similar to 6061, slightly higher tensile strength |

Structural components, marine applications

|

| Aluminum 5083-H111 | 3.3547 | H111 | AlMg4.5Mn0.7 | Excellent corrosion resistance, weldable |

Marine applications, chemical equipment

|

| Aluminum 6063 | EN AW-6063 | – | AlMg0,7Si | Good mechanical properties, heat treatable, weldable |

Aerospace applications, extrusion profiles

|

| Aluminum 5052 | EN AW-5052 | – | AlMg2,5 | Excellent corrosion resistance, weldable |

Marine applications, chemical equipment

|

| Aluminum 2024-T351 | 3.1355 | T351 | AlCu4Mg1 | High strength, excellent fatigue resistance |

Aerospace applications, structural components

|

| Aluminum 7050 | EN AW-7050 | – | AlZn6CuMgZr | Excellent mechanical properties, good ductility, high strength, toughness, fatigue resistance |

Aerospace applications, structural components

|

| Aluminum MIC6 | – | – | – | Lightweight, easily machinable, free from tension, contaminants, and porosity | Machining applications |

| Aluminum 6082-T651 | 3.2315 | T651 | AlSi1MgMn | Similar to 6061, slightly higher tensile strength |

Structural components, marine applications

|

| Aluminum 2017A | 3.1325 | – | AlCu4MgSi | Higher ductility and formability than 2014, intermediate strength | Structural components |

| Aluminum 7075-T651 | 3.4365 | T651 | AlZn5,5MgCu | Excellent strength-to-weight ratio, high strength and hardness |

Aerospace, military, high-stress applications

|

| Aluminum 2014 | 3.1255 | – | AlCu4SiMg | Easily machinable, high strength when hardened, prone to corrosion |

Aerospace applications, structural components

|

| Aluminum 6061-T651 | 3.3211 | T651 | AlMg1SiCu | High strength, excellent machinability, good weldability |

Aerospace, automotive, construction

|

| Aluminum 7075-T7351 | 3.4365 | T7351 | AlZn5,5MgCu | High strength, excellent machinability, good fatigue resistance |

Aerospace, defense, automotive, transportation

|

Die-cast aluminum alloys can form the basic shape of components. For areas requiring assembly, excess aluminum is removed via CNC machining (milling/turning), enabling efficient and cost-effective mass production of lightweight mechanical parts. The commonly used materials for die-cast aluminum CNC machining are as follows.

Common Die-Casting Aluminum Alloys for CNC Machining(Domestic & International)

Domestic Grades (GB/T 15115-2009, China)

- YL102 (Al-Si12): Excellent fluidity, suitable for die-casting complex components; applied in instrument housings, electrical enclosures.Equivalent grades: ADC1, A413.0, AlSi12

- YL104 (Al-Si10Mg): Medium strength, good hot crack resistance and weldability; applied in hydraulic parts, motor end covers.Equivalent grades: ADC3, A360, AlSi10Mg0.3

- YL112 (Al-Si9Cu4): High strength, superior machinability; applied in automobile cylinder blocks, gearbox housings.Equivalent grades: ADC10, A380, AlSi9Cu3

- YL113 (Al-Si11Cu3): High fluidity, good corrosion resistance; applied in thin-walled complex components, electronic enclosures.Equivalent grades: ADC12, 383.0, AlSi11Cu3

- YL117 (Al-Si17Cu5Mg): High silicon content for wear resistance, excellent thermal conductivity; applied in engine cylinder liners, pistons.Equivalent grades: ADC14, B390, AlSi17Cu5Mg

International Mainstream Grades

- ASTM (USA)

- A380: Universal grade with balanced comprehensive properties; for automotive/industrial components

- A356 (Al-Si7Mg): Heat-treatable for reinforcement; for wheel hubs, structural components

- A413.0: High silicon content, excellent fluidity; for thin-walled components

- JIS (Japan)

- ADC12 (Al-Si11Cu3): High fluidity, ideal for complex die-castings

- ADC10 (Al-Si9Cu4): Better toughness, for large die-cast components

- ADC3 (Al-Si10Mg): Good hot crack resistance, for hydraulic parts

-

- AlSi12: High silicon content, superior fluidity

- AlSi9Cu3: Universal grade, equivalent to A380

- AlSi7Mg0.3: Equivalent to A356, high strength and toughnessEN (Europe)

Core Grade Cross-Reference Table

| Domestic (China) | ASTM (USA) | JIS (Japan) | EN (Europe) |

|---|---|---|---|

| YL102 | A413.0 | ADC1 | AlSi12 |

| YL104 | A360 | ADC3 | AlSi10Mg0.3 |

| YL112 | A380 | ADC10 | AlSi9Cu3 |

| YL113 | 383.0 | ADC12 | AlSi11Cu3 |

| YL117 | B390 | ADC14 | AlSi17Cu5Mg |

Key Material Selection Guidelines for Die Casting Aluminum CNC Machining Components.

- Al-Si/Cu series (YL112/YL113, A380, ADC12) are the first choice for most general die-casting components.

- For high strength and toughness requirements, select Al-Si/Mg series (YL104, A356) featuring heat-treatable reinforcement.

- For wear resistance/thermal conductivity needs, opt for high-silicon series (YL117, B390, ADC14).

Aluminum Alloy Grades for Sand Casting, Gravity Die Casting & Low Pressure Die Casting + Process Differences & Universal Grades

I. Alloy Grades for Each Process (GB/T 1173 China Domestic + International Equivalents, divided into Universal & High-requirement Grades)

1. Sand Casting

International Equivalents: A356.0, A413.0, A360.0, 208.0

Niche Special Grades (for thick and large wall components only): ZL105

International Equivalent: A242.0

2. Gravity Die Casting

Universal Mainstream Grades (100% compatible with sand casting, industry first choice): ZL101, ZL102, ZL104, ZL201

International Equivalents: A356.0, A413.0, A360.0, 208.0

High-requirement Special Grades (optimized for hot crack resistance & low impurity, suitable for metal molds): ZL101A, ZL104A

International Equivalents: High-purity A356.0, A357.0

3. Low Pressure Die Casting (LPDC)

Universal Mainstream Grades (80% compatible with sand/gravity die casting, core selection): ZL101A, ZL104, ZL201

International Equivalents: A356.0, A360.0, 208.0

High-requirement Special Grades (high density & low porosity, suitable for high-precision and high-stress components): ZL101B, ZL205A

International Equivalents: A357.0, 201.0, A354.0

⚠️ Not Recommended for Use: Die-casting exclusive grades (YL112/113, ADC10/12, A380), sand casting niche grade ZL105

II. Core Differences of the Three Casting Processes (Key Basis for Grade Selection)

| Comparison Dimension | Sand Casting | Gravity Die Casting | Low Pressure Die Casting |

|---|---|---|---|

| Mold Type | Sand mold (good collapsibility & air permeability) | Metal mold (fast heat dissipation, no collapsibility) | Metal mold + low-pressure filling |

| Molding Pressure | None (natural gravity) | Natural gravity | Low pressure (0.05-0.3MPa) |

| Casting Density | Low (prone to porosity & shrinkage) | Medium | High (close to die casting) |

| Core Alloy Requirements | No stringent requirements, adaptability first | Good hot crack resistance & moderate fluidity | High purity, excellent hot crack resistance & heat-treatable |

| Typical Applications | General non-stress components / rough blanks | Medium & low stress structural components / general mechanical parts | High-precision & high-stress components (wheel hubs, cylinder heads) |

| Post-processing | Extensive CNC finishing required | Minor CNC finishing required | Precision machining (for assembly fit) |

III. Universal Core Grades for the Three Processes (cross-process compatible, mature supply chain & cost-effective)

China Domestic Grades

International Equivalents

Core Characteristics of Universal Grades

- Heat-treatable for strength and toughness enhancement, adaptable to different stress requirements via subsequent processes;

- Moderate fluidity, compatible with the slow cooling of sand molds and fast cooling of metal molds;

- Low impurity content, less prone to cracking and shrinkage porosity, high forming qualification rate across processes;

- Excellent machinability, suitable for CNC turning/milling, meeting assembly precision requirements.

Application Scenarios of Universal Grades

- Heat treatment requirements: Forged aluminum profiles are pre-heat-treated, usually to T4/T6 temper; cast aluminum products can be post-heat-treated, generally also to T6 temper. Die-cast aluminum products are typically not suitable for heat treatment.

- Product structure: Complex structures require blanks to be produced via sand casting, gravity die casting or low pressure die casting, followed by machining to meet assembly precision requirements.

- Product dimensions: Some oversized products can only be manufactured by aluminum sand casting, as other casting methods are limited by the size of casting equipment.

- Production efficiency: Die casting combined with machining offers the highest efficiency, while sand casting paired with machining has the lowest efficiency.

- Surface roughness & precision: Sand casting yields the roughest surface and lowest precision, followed by gravity die casting, then low pressure die casting; pure machining achieves the highest surface precision.

- Unit cost: For sufficiently large order quantities, the unit cost of die casting plus machining is the lowest after the mold cost is evenly amortized.

- Internal material density: Aluminum profiles are formed by forging or extrusion, resulting in an extremely dense internal structure. In contrast, blanks from casting and die casting often have internal defects such as porosity or shrinkage porosity.