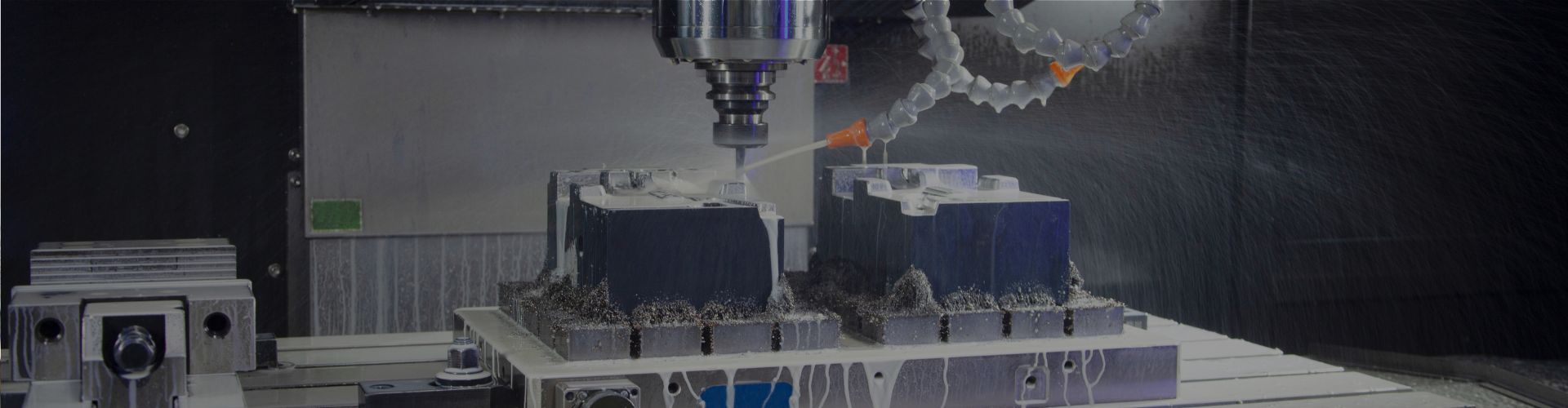

What is CNC Milling?

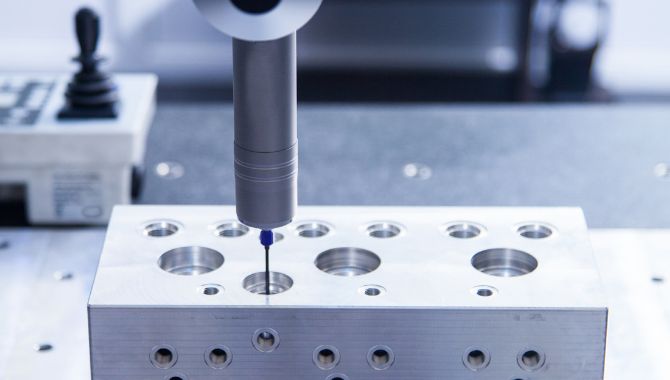

CNC milling is a manufacturing process in which parts or materials are securely affixed to a fixture, and the cutters on the machine follow a computer numerical control (CNC) program for precise operations. This process has evolved from traditional manual milling methods.

Various machines are employed in CNC milling, including milling machines, CNC machining centers, drill and tapping machines, and turning-milling machines, each specialized for specific milling tasks.

- CNC machining centers are available with 3 axes, 4 axes, and 5 axes, and the complexity of the machining tasks they can handle increases with the number of axes.

- Machines equipped with more axes can produce intricate and intricate milled parts.

CNC Millling Parts with Different Materials

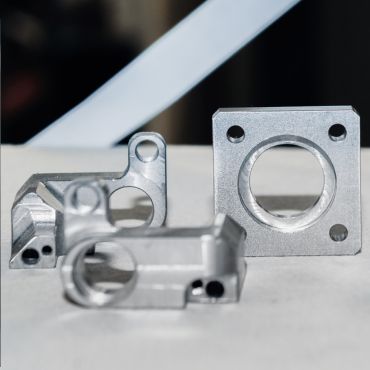

The images below showcase our successful CNC milling projects, but it’s important to note that Yontone’s CNC milling techniques capabilities extend far beyond these examples. We are equipped to machine a wide array of materials, and our expertise is not limited to the cases displayed here. We have the capacity to fulfill a diverse range of machining requirements to meet your specific needs.

We offer both large-scale custom CNC milling parts and small milling products, with sizes ranging from a maximum of 700mm to a minimum of 2mm.

Different types of CNC milling materials are suitable for CNC milling programs, and these include metals, plastics, wood, and even certain composites.

More CNC Milling Parts

CNC milling parts have a wide range of applications in various industries, including medical equipment, automotive engine systems, steering systems, new energy, fishing, marine, mining, and more.

Yontone is a leading OEM milling supplier in China, offering different types of CNC milling services, CNC turning services, and CNC machining services on different materials.

Online CNC Milling Processes

Online CNC milling processes refer to the utilization of computer numerical control (CNC) milling services available over the internet. These services enable individuals or businesses to access and request CNC milling and machining operations remotely through online platforms. Here is an overview of the typical steps and components of online CNC milling processes:

- Online Quoting and Ordering:

- Customers typically begin by visiting the website of an online CNC milling service provider.

- They upload or input their design files (usually in CAD/CAM formats) and specify project requirements, including material, quantity, tolerances, and any special instructions.

- The online platform generates a price quote based on the provided information. Customers can review and confirm the order.

- Design Review and Optimization:

- Some online CNC milling services offer design review and optimization. This involves checking the uploaded design for potential issues or improvements and working with the customer to refine the design if necessary.

- Material Selection:

- Customers choose the material they want their parts to be machined from. This can include metals, plastics, wood, or composites, as mentioned earlier.

- CNC Machining Setup:

- The online service provider prepares the CNC machine and the necessary tooling based on the provided design and material specifications.

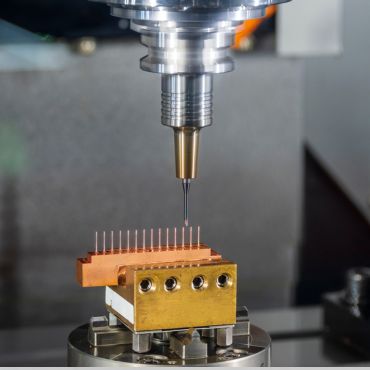

- CNC Milling and Machining:

- The CNC machine follows the programmed instructions to cut, shape, and refine the material, creating the desired part or component.

- Quality Control:

- After machining is complete, quality control measures are typically taken to ensure the parts meet the specified tolerances and quality standards.

- Inspection and Testing:

- Depending on the complexity of the part and customer requirements, inspection and testing may be conducted, which can include dimensional measurements and functional testing.

- Finishing and Surface Treatments:

- Additional finishing processes like deburring, polishing, or applying surface treatments can be carried out if requested.

- Packaging and Shipping:

- The finished parts are carefully packaged to prevent damage during transit and then shipped to the customer’s specified address.

- Customer Feedback and Support:

- Online CNC milling service providers often seek feedback from customers to ensure satisfaction and to continually improve their services.

- Customer support is available for inquiries, clarifications, or any issues that may arise during the process.

Online CNC milling services offer convenience, access to a wider range of machining capabilities, and the ability to complete projects without the need for physical presence at a machining facility. Video conferences during the whole process is very supportive. This approach has become increasingly popular for both prototyping and production purposes.

Advantages of CNC Milling Process

In comparison to die casting or traditional casting methods, CNC milling offers the advantage of a significantly lower Minimum Order Quantity (MOQ). Additionally, CNC milling is often the preferred choice for creating prototypes due to its versatility and precision.

CNC milling processes offer exceptional precision, achieving accuracy levels down to the submicron range. For typical products, tight tolerances can be consistently maintained to within a few microns.

CNC milling parts exhibit a high level of consistency in terms of size and dimensions, ensuring the smooth progression of assembly processes.

The accuracy of CNC milling parts is guaranteed through the precise setup of milling machines and the meticulous programming by engineers. The impact of human factors on the operator is minimal, resulting in a low error rate.

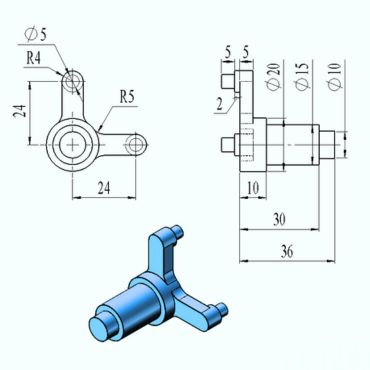

Milling Fixture Design

Milling fixtures are pivotal in CNC milling, and our in-house engineers, with 8+ years of experience, specialize in designing high-efficiency fixtures.

- We recognize their crucial role and offer dedicated fixture design services to enhance CNC milling quality.

- We focus on delivering exceptional value, tailoring designs to your needs, ultimately boosting efficiency and precision for your CNC milling process.

Cutting Routine Design

The design of cutting routines significantly impacts the production time for individual products. The more rational the design, the shorter the time required, resulting in lower costs and increased efficiency. It is essential to balance precision with productivity, ultimately enhancing production capacity.

Quality Control

At Yontone, as a leading CNC milling manufacturer, we take quality seriously.

- We have our own QC lab equipped with advanced testing equipment, including CMM checking machines, roughness meters, projectors, hardness meters, pressure testing, tensile testing, salt spray testing, X-ray testing, and metallographic testing.

- Our commitment to quality and precision is unmatched in the industry, ensuring that our CNC milling products meet the highest standards.

- We take pride in being your trusted source for CNC milling, delivering top-notch quality from our factory to your project.

Why Choose Yontone for Your CNC Milling Needs

When you’re searching for a CNC milling partner, what really matters is finding a solution that ticks all the right boxes for you. At Yontone, we’ve designed our services with your needs in mind:

- Expertise and Experience: Benefit from a team with extensive CNC milling experience. Our professionals have spent 15 years perfecting their craft, ensuring the best results for your projects.

- Diverse Capabilities: Find everything you need in one place. From online quotations to online video conferences, we offer a wide range of services tailored to your specific requirements.

- Quality Assurance: Enjoy peace of mind with our in-house quality control lab, equipped with advanced testing equipment. Your products are guaranteed to meet the highest standards.

- Efficiency: We know time is money. Our focus is on enhancing the efficiency of your CNC milling projects while maintaining precision, ensuring faster turnaround times.

- Customized Solutions: We understand that one size doesn’t fit all. Our services are tailored to your unique needs, delivering the best results for your projects.

- Reliability: Count on Yontone for consistent top-notch quality and adherence to promised deadlines. Your success is our priority.

At Yontone, we provide the tools you need to succeed. Whether you’re seeking an online quotation, an online video conference, or top-notch CNC milling services, we’ve got you covered. Your success is our success, and we’re here to make your projects a resounding triumph.

Wild Application Fields of CNC Machining Parts

Yontone is capable of machining high-precision, high-strength, and wear-resistant parts.

Its CNC milling parts can meet the mass production requirements of automotive manufacturing, including engine, transmission, and chassis parts.

Yontone is capable of machining high-precision, high-strength, and lightweight parts.

Its CNC milling parts are widely used in aerospace, including various parts of airplanes, rockets, and spacecraft.

Yontone CNC milling is capable of machining complex geometries with high precision and efficiency.

In mechanical manufacturing, it is used to manufacture various machine parts, including shafts, gears, bolts, and nuts.

Yontone CNC milling techniques are capable of machining high-precision and complex geometries and can meet the mass production requirements of electronic product manufacturing.

In electronic product manufacturing, it is used to manufacture various components, including circuit boards and connectors.

Yontone’s CNC milling parts are capable of machining high-precision and reliable parts.

They are used in the manufacturing of various medical device components, including surgical instruments and implants.