Mould Making Equipments

The equipment used for manufacturing die casting mold includes milling machines, drilling machines, lathes, grinding machines, wire EDM machines, and electrical discharge machining (EDM) machines. The combination and utilization of these machines enable Yontone to achieve comprehensive processing of die casting mold components, ensuring that the products meet design specifications and quality standards.

Here is a brief overview:

Yontone uses CNC Planer Milling Machines to mill the mold steel of the mold frame and mold matrix on both the exterior and interior surfaces. This process aims to achieve the dimensions, flatness, and precision specified in the blueprint for the mold frame and mold cavity.

Yontone utilizes CNC Machining Centers to mill the central area of the mold frame where the mold core is positioned. Simultaneously, performing rough and finish milling on the mold core to shape the exterior of the product. The majority of the mold machining process is accomplished through CNC Milling Machines.

Yontone primarily employs EDM (Electrical Discharge Machining) machines for processing intricate features in die casting molds, especially in areas with irregular shapes, no radii, and extremely deep or fine details that cannot be efficiently machined using CNC machining centers.

Yontone utilizes WEDM (Wire Electrical Discharge Machining) machines to process various shapes and features in die casting mold components, including grooves, ejection pin holes, slots, chamfers, and more. The primary focus is on perforation processes.

Yontone employs radial drilling tools in mold production to machine various types of holes, including through-holes, blind holes, counterbore holes, threaded holes, holes for die casting mold cooling water pipes, and lead holes for WEDM processes.

Yontone utilizes a mold clamping machine to close the parting surfaces of the upper and lower molds in the mold assembly process. It employs hydraulic or pneumatic pressure to bring the mold’s parting surfaces together, creating the mold cavity. Precision control of the mold cavity is achieved by adjusting pressure, clamping speed, and other parameters.

Die Casting Equipments

Die-casting workshop is equipped with cold chamber die-casting machines, hot chamber die-casting machines, as well as shot blasting machines, polishing machines, and other equipment.

Yontone is dedicated to delivering high-quality die-casting services to both domestic and international clients.

Below are the die casting machines:

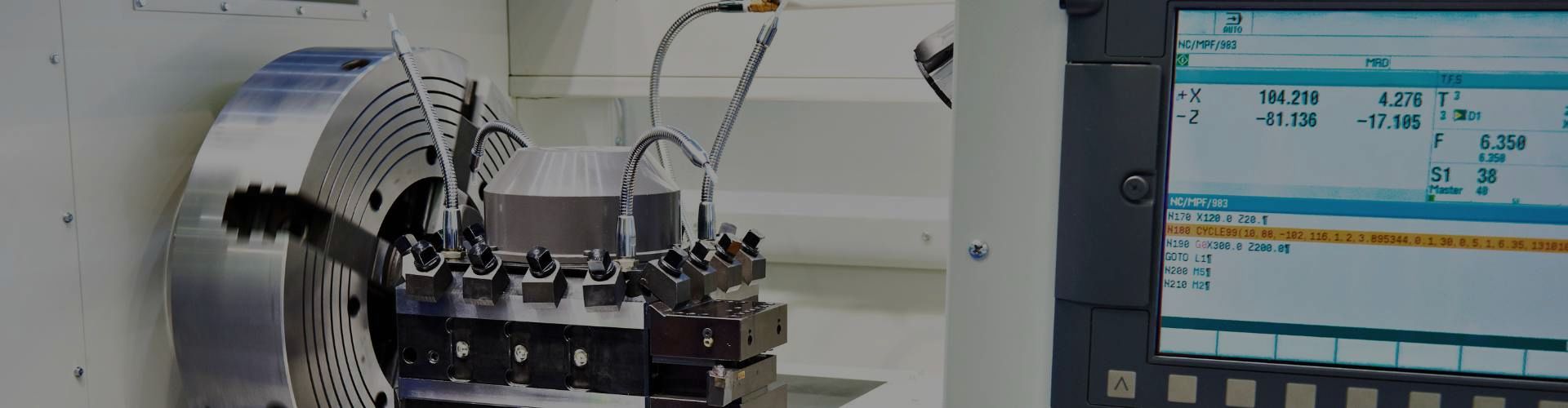

CNC Machining Equipments

CNC Machining Equipment primarily involves the precision processing of metal materials or cast metal blanks into components with dimensions specified in the drawings, utilizing computer-controlled machine tools. This process meets the requirements for assembly and integration.

Yontone offers turning, milling, and turning-milling composite machining services.

The materials that can be processed include aluminum alloy, zinc alloy, copper alloy, iron, steel, stainless steel, titanium alloy, and ductile iron, among others.

Below are the machining facilities:

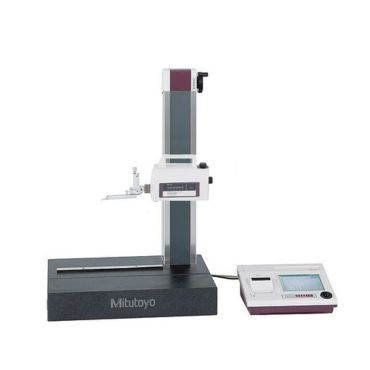

Quality Control Equipments

Inspection machines primarily refer to inspecting parameters such as product dimensions, appearance, roughness, etc., that may impact subsequent processes.

Yontone, based on the final purpose of the customer’s product and the requirements outlined in the drawings, provides inspection reports including CMM inspection, two-dimensional inspection, hardness inspection, and other relevant assessments.

Below are some of the QC equipments: