Pneumatic gauges are ideal for measuring precision components that require high precision.

Strict testing procedures coupled with high-precision manufacturing capabilities enable us to ensure that molds and parts are produced with tight tolerances to meet your custom machining needs for sophisticated and complex parts.

1. What is the pneumatic gauge working principle?

The measurement principle of the pneumatic gauge is a comparative measurement method. The measurement method is to convert the length signal into an air flow signal, and pass the float mark value in the graduated glass tube, which is called a float-type pneumatic measuring instrument; or convert the air signal into an electric signal through a gas-electric converter. Indication value, called electronic column pneumatic measuring instrument. The pneumatic measuring instrument is a measuring instrument that can be assembled by multiple units. It can be matched with different pneumatic probes to measure various parameters.

2. Advantages of using a pneumatic gauge:

Due to its many advantages, pneumatic measuring instruments have been widely used in the machinery manufacturing industry. Its advantages are as follows:

1. There are many measurement items, such as length, shape and position error, etc., especially for some measurements that are difficult to solve with mechanical measuring tools and measuring instruments, such as: sounding hole inner diameter, small hole inner diameter, narrow groove width, etc., use pneumatic measurement to compare easy to accomplish.

2. The magnification of the measuring instrument is high, and the human error is small, which will not affect the measurement accuracy; there is no mechanical friction during operation, so there is no return error.

3. The operation method is simple, the reading is easy, continuous measurement can be performed, and it is easy to see whether each size is qualified.

4. Realize that the measuring head is not in direct contact with the measured surface, reduce the influence of the measuring force on the measurement results, and avoid scratching the surface of the measured part, which is especially suitable for the measurement of thin-walled parts and soft metal parts.

5. Due to the non-contact measurement, the measuring head can reduce wear and prolong the service life. The main body of the pneumatic measuring instrument and the measuring head are connected by a hose, which can realize long-distance measurement.

6. The structure is simple, the work is reliable, and the adjustment, use, and maintenance are very convenient.

a. Measurable items suitable for pneumatic measurement.

| Inner diameter | Outer diameter | Conicity | Roundness |

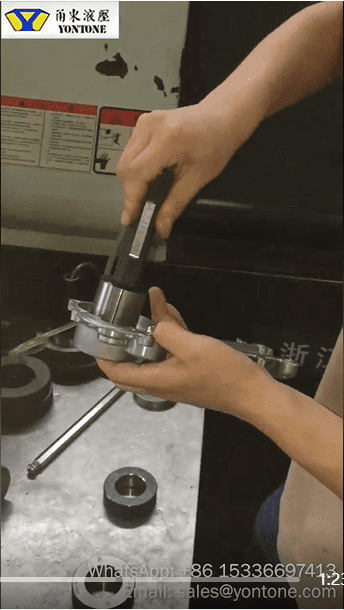

We can see the inside diameter pneumatic gauge in this picture on the left. The working principle and the working principle of the outer diameter pneumatic gauge.

The shape and angle of their air nozzles are different.

The size of each pneumatic gauge nozzle is customized according to the size of the product we need to inspect.

Pneumatic gauges are universal.

b. The measurement accuracy of pneumatic gauges.

A length measuring tool consisting of a pneumatic length sensor, indicator (gauge), air filter and voltage regulator. Non-contact measurement can be performed using a pneumatic gauge, and the measurement efficiency is very high. Pneumatic gauges are suitable for measuring internal and external dimensions in mass production, and can also be used to measure hole distance and shaft hole fit clearance. When measuring with a pneumatic measuring instrument, it is necessary to match the corresponding probe according to the size to be measured (Picture above) The pneumatic inner diameter probe has a simple structure and is very suitable for measuring the aperture. It can measure small holes as small as 1.5mm in diameter. The indication range of the pneumatic gauge is small, generally ±20 to ±100 microns. According to the different indication ranges, the common graduation values are 0.5 microns, 1 microns and 2 microns. The allowable error is generally not greater than one division value. Pneumatic measuring instruments are mainly divided into two types: pressure type and flow type.

3. A video of our inspectors using a pneumatic gauge to test the inner diameter of a product.

This video has been posted on the company homepage Linkedin, please click below picture, you can see the video.

Pneumatic Gauge Checks The Inner Diameter Of Aluminum Die Casting Products Optimized

https://www.linkedin.com/feed/update/urn:li:activity:6980428282894704640

Welcome to contact us to purchase mold and die casting parts, and machined parts.

WhatsApp: +86 15336697413

Email: sales@yontone.com

- 3D Scanning and Modeling

- About Material

- Aluminum Die Casting

- Anodizing

- Chair Base

- Character History

- CNC Machining

- Coffee Maker Handle

- Die Casting Part Porosity Check

- Electrophoresis

- Iron Steel Casting

- LED Street Light Housing

- Material Composition

- Material Performance

- Mould Making

- Package

- Pots, Pans

- Product

- Production Procedure

- QC

- Sales Manager (Project Manager)

- Sample Room

- Sand Casting

- Size Checking

- Street Lights

- Surface Treatment

- Uncategorized

- Zinc Die Casting