What is zinc die casting?

Zinc die-casting components are pressure-cast parts manufactured using a process that involves the use of a pressure die-casting machine equipped with a preloaded die-casting mold. In this process, heated liquid zinc or zinc alloy is poured into the casting machine’s inlet, and then, under high pressure applied by the machine’s piston, the zinc alloy is forced into the mold, taking on the shape and dimensions defined by the mold. These components produced through this method are commonly referred to as zinc alloy die-casting parts.

While cold-chamber die-casting machines can also be used for zinc alloy die-casting, the most frequently utilized method is the hot-chamber die-casting machine. This preference is due to the high production efficiency it offers, which helps reduce the cost of die-cast components. Additionally, it ensures excellent flow and filling properties of the molten zinc alloy. Consequently, zinc alloy die-casting has become a prevalent manufacturing method for a wide range of industrial components and products, meeting the diverse needs of various industries.

Zinc alloy is widely used in die casting industry, zinc metal material with several advantages that make it widely used in various fields:

- Low Melting Point and Excellent Flowability: Zinc alloys have a low melting point, making them easy to heat and cast. This excellent flowability makes them suitable for manufacturing complex-shaped parts.

- High Density and Strength: Zinc alloys have relatively high density and strength, making them suitable for applications requiring wear resistance and mechanical strength.

- Smooth Surface Finish: Zinc alloy die-casting parts typically have smooth surfaces and do not require additional surface treatments, reducing post-processing costs.

- Thermal Stability: Zinc alloys exhibit good mechanical properties at room temperature, making them suitable for various environments.

- Multiple Alloy Options: There are various zinc alloys to choose from to meet different application requirements. Common ones include the ZAMAK series and ZA series alloys, such as ZAMAK 2, ZAMAK 3, ZAMAK 5, ZA-8, and more.

- Wide Range of Applications: Zinc alloy die-casting parts find extensive use in industries such as instrumentation, automotive part casings, bathroom handles, and more, catering to the needs of diverse sectors.

It’s important to note that the performance of zinc alloys may deteriorate in high-temperature and low-temperature environments, so the working temperature range of zinc die casting parts should be considered when selecting zinc alloy materials. Additionally, zinc die casting products have relatively poor corrosion resistance, and excessive impurities in the alloy may lead to aging and deformation of castings. Furthermore, zinc alloy die-casting parts may exhibit aging effects, with a potential decrease in strength after prolonged use. Therefore, these factors should be carefully considered for specific applications.

Zinc Die Casting Parts with Different Applications

Due to the excellent flowability and plasticity of zinc and zinc alloys as metal materials, and the fact that the casting process takes place in zinc alloy die-casting machines under working pressure, zinc alloy die-casting components can be manufactured in various complex shapes with high precision and smooth surfaces. This significantly reduces the need for subsequent mechanical processing and the amount of zinc and zinc alloy used. This not only saves on electricity and material costs but also greatly reduces labor costs.

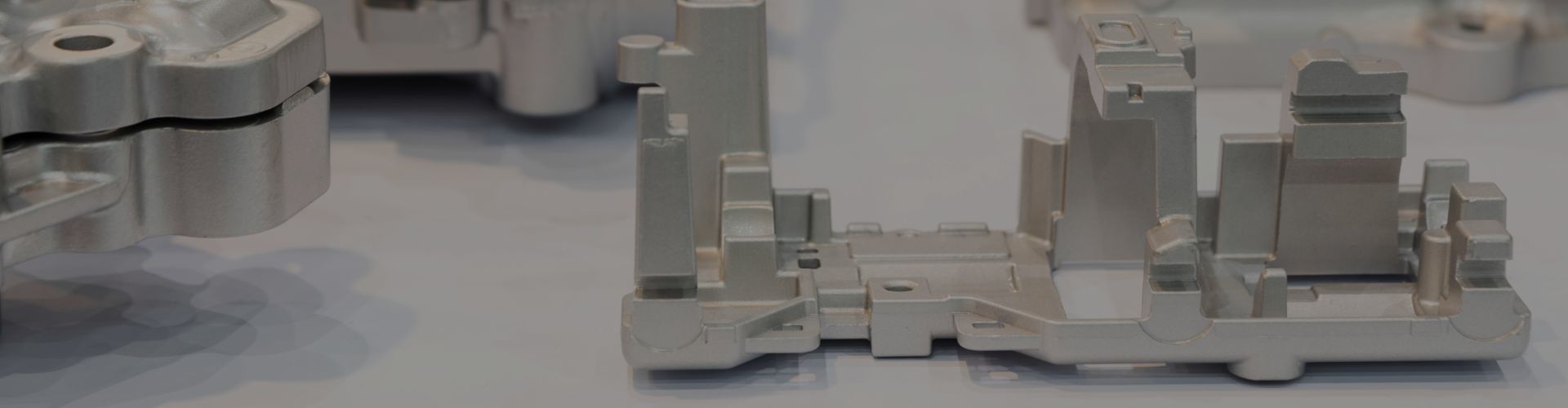

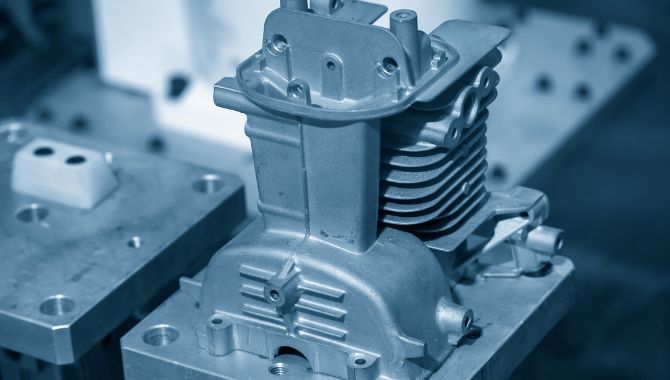

Zinc alloy is heavier than aluminum alloy, but it offers superior surface treatment capabilities, corrosion resistance, and lower manufacturing costs. Therefore, it becomes the preferred choice for many appearance shell products. In the image, there are zinc die-cast components made by Yontone such as the packing meter housing, door hinge, and other small accessories.

Yontone produces zinc alloy die-cast doors and window handles that are lighter and more affordable compared to copper alloy. These handles can undergo various surface treatments, such as chrome plating, powder coating, polishing, and more. They are both aesthetically pleasing and durable.

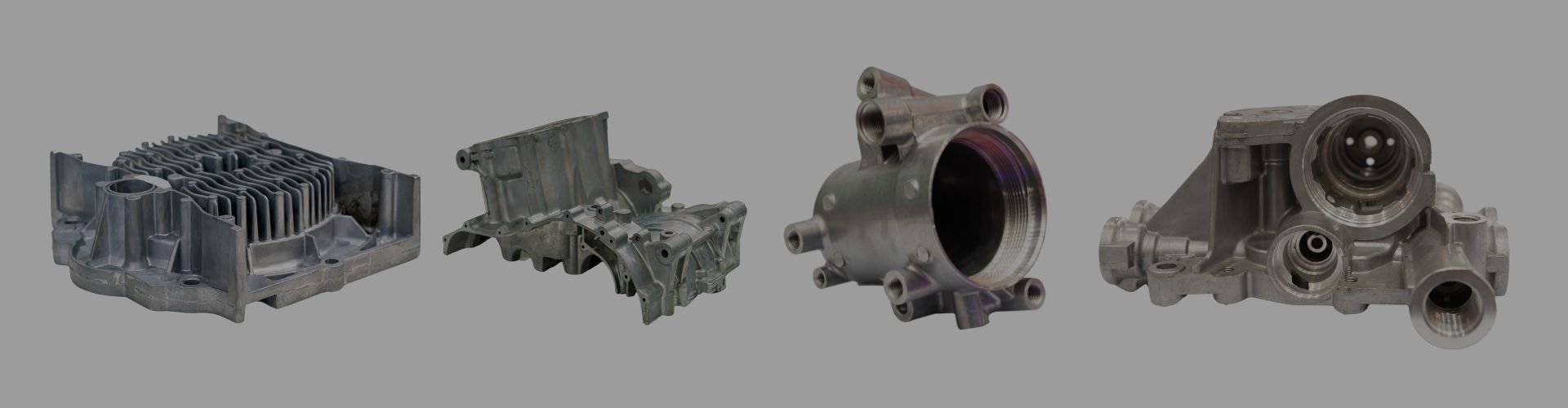

More High Pressure Zinc Die Casting Parts

Zinc and zinc alloys have good thermal conductivity, a low shrinkage ratio, and outstanding machinability. Therefore, zinc alloy die-casting components are widely used in numerous fields, including electronic products, automotive manufacturing, gas turbine production, motorcycle manufacturing, electric motor production, gasoline pump manufacturing, transmission system machinery and equipment manufacturing, instrumentation, landscaping and cleaning, power engineering, architectural decoration, bathroom handles, furniture accessories, handbag accessories, belt buckles, wrenches, jewelry boxes, picture frames, medals, LOGO plaques, keychains, bottle openers, Christmas gifts, cellphone accessories, ashtrays, metal toys, balance weights, eccentric wheels, and various mechanical parts.

Zinc Die Casting Process - from Mould Design to Delivery

Yontone company offers a one-stop solution that includes zinc alloy mold design and production, zinc alloy die-casting, machining, as well as polishing, electroplating, and other surface treatments.

- This comprehensive service eliminates the need for customers to coordinate with multiple suppliers for molds, die-casting, and surface treatment.

- It also prevents potential quality disputes between mold design companies and die-casting factories.

- This simplifies the customer’s workflow, reduces the workload for procurement teams, and ensures clear supplier responsibilities.

Advantages of Zinc Die Casting Process

Zinc alloy products manufactured using die-casting molds typically yield 1-40 cavities per mold. Due to it’s lower specific heat capacity and rapid cooling rate, zinc alloy die-casting efficiency for the same product is 1.5 times that of aluminum alloy die-casting. This efficiency contributes to faster production and reduced manufacturing costs.

Zinc alloy’s low affinity with iron, coupled with its excellent thermal contraction characteristics, typically results in mold draft angles of 1-3 degrees when demolding. When necessary, it is even possible to achieve zero draft angles, allowing for precise and intricate product designs.

Zinc alloy has a density three times that of aluminum alloy, resulting in high hardness and a strong metallic feel. This characteristic makes it suitable for various surface treatments, making it a preferred choice for manufacturing many electronic products. It offers an excellent strength-to-weight ratio, contributing to lightweight yet robust product designs.

Zinc alloy’s excellent flowability allows for the production of thinner and more intricate products compared to aluminum alloy die-castings. Wall thicknesses ranging from 2-4mm are achievable, and when necessary, even thinner walls as fine as 0.6mm to 1mm can be produced. This versatility in shaping makes zinc alloy an ideal choice for complex and detailed product designs.

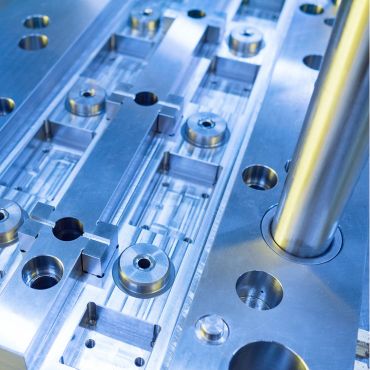

Zinc Die Casting Mould Design & Manufacturing

The metallic properties of zinc alloys can differ from aluminum alloys, zinc alloy die-casting generally employs hot chamber die-casting machines. Therefore, specialized zinc alloy die-casting mold designers are required for mold design. The design of the sprue, runners, vents, and slag traps is meticulously crafted to ensure the final die-casting exhibits optimal performance and product quality.

Zinc alloy die-cast products usually require post-processing such as polishing and electroplating, placing high demands on the surface quality of the die-cast parts. It is crucial to ensure the complete filling of the zinc alloy die-casting components without any porosity.

Yontone company has a professional mold design team with over twenty years of experience, providing custom mold designs tailored to specific project requirements, ensuring the best production efficiency and product quality. This is highly important in the zinc alloy die-casting process.

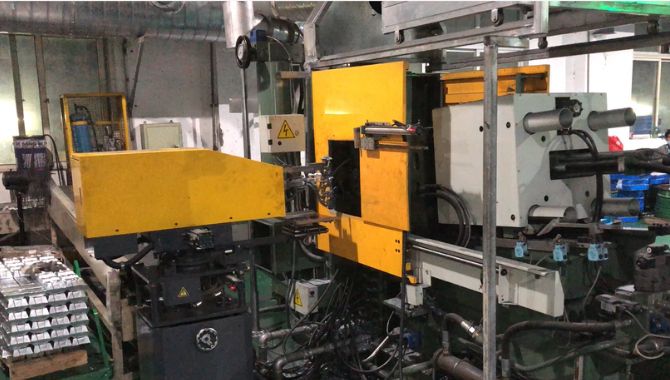

Manual & Automatic Zinc Die Casting Process

Zinc alloy has good fluidity, a low melting point, and high die-casting efficiency.

We flexibly choose the appropriate zinc die casting production method to meet the needs of customers with different scales and requirements:

- For small-batch orders, we employ manual die-casting.

- For products that can be produced on a large scale, we utilize fully automated die-casting, running 24/7 without interruption. This not only saves on labor costs but also improves efficiency.

Manual Finishing for Zinc Alloy Die-Cast Parts

Yontone currently relies primarily on manual labor for the removal of sprues, deburring, and polishing of zinc alloy die-cast products.

The shape and polishing requirements vary for each product, and manual polishing offers greater flexibility in handling diverse shapes and requirements, all while helping to control costs.

What makes Yontone the preferred choice as your zinc die casting supplier?

One-stop: Custom Zinc Alloy Die Casting Parts – If you require high-quality products with tight deadlines, Yontone is your ideal choice. We provide end-to-end services, from designing zinc alloy die-casting molds to casting, machining, and surface finishing. For urgent orders, we prioritize production to ensure on-time delivery while maintaining product quality.

Raw Materials: High-quality and stable zinc alloy casting requires high-purity zinc to be used, with strict limits on impurities such as iron, aluminum, and lead in the alloy. We procure high-quality zinc alloy raw materials from large Chinese zinc alloy material factories to ensure the quality of our zinc alloy products from the source.

Mold Design: Since zinc alloy die-casting parts typically undergo electroplating and other surface treatments, the design of the mold’s inlets, runners, and venting is crucial. The absence of internal porosity in the product is essential to prevent bubbles during subsequent surface treatments, which could affect product appearance and lead to rejection. Zinc alloy mold design differs from aluminum alloy mold design, and Yontone has dedicated engineers skilled in optimizing material usage, increasing yield, and enhancing production efficiency to deliver high-quality zinc alloy die-casting products to customers.

MOQ (Minimum Order Quantity): Our company possesses sufficient machinery and equipment to handle large, continuous orders from major clients while also accommodating small-batch trial orders for small businesses. We support high-capacity requirements for large clients and are committed to helping smaller clients gradually expand their market share.

Quality Control (QC): Quality management is paramount for zinc alloy die-casting parts because of the high production efficiency. Failure to detect issues promptly can result in a significant volume of rejected products. Therefore, we conduct frequent inspections during the production process, with visual inspections of products from automatic die-casting machines every hour to ensure both high yield and reduced waste. Additionally, before shipment, we perform random or full inspections based on standard ratios or customer requirements, with surface-treated products requiring a full inspection of appearance and sampling for dimensions.

Lead Time: Our standard products follow a regular production process, typically with a lead time ranging from one month to 45 days. Customers can also negotiate for expedited orders. We are committed to meeting the promised delivery date without delay. Quality and delivery time are our top priorities for orders.

Equipment: Our zinc alloy die-casting machines are equipped with mechanical arms, and automatic feeding, and spraying devices, significantly enhancing production efficiency while reducing labor costs.

Price: In any industry, proficiency improves efficiency, and efficiency leads to cost reduction. As a company with over 35 years of mold design & manufacture experience and over 20 years of zinc alloy die-casting experience, Yontone provides customers with high-quality products that offer excellent value for money while ensuring mold longevity and product quality. Our goal is to deliver 5-star products at 3-star prices.

Commitment: Integrity is the foundation of Yontone’s existence. As a company aspiring to be a century-old enterprise, we aim to provide customers with competitively priced, high-quality products delivered on time, and excellent service. We strive to grow together with our customers.

Wild Application Fields of Zinc Die Casting

Due to the excellent heat dissipation and thermal conductivity of zinc alloy die-cast components, they are widely utilized in various electronic device housings, including those for smart door locks, monitors, cameras, parking card readers, and more.

Many zinc alloy die-cast components are also crafted into heat sinks and various connectors.

Zinc die casting parts, have high strength, lightweight, and corrosion resistance. In automotive manufacturing, zinc alloy die-casting is extensively used to produce components.

Yontone supplies zinc die casting engine parts, exhaust system components, brake system parts, and body structures.

In the aerospace industry, zinc alloy die-casting is utilized in the manufacturing of various components for aircraft and spacecraft. This is because it can provide excellent strength and lightweight characteristics.

Zinc alloy die-casting is also employed in the military industry, used in the production of components for military vehicles, accessories, and more.

Zinc alloy die-casting is commonly employed in the production of household items. Yontone supplies door handles and window accessories, furniture hardware, and lamp casings in zinc die casting services.

Zinc alloy die-cast components are heavier than aluminum alloy die-cast components due to the higher density of zinc alloy. After surface treatment, zinc alloy components exhibit a better and more textured appearance

In the manufacturing of medical equipment, the corrosion resistance and processability of zinc alloy die-casting make it an ideal material. Yontone supplies production of surgical tools, medical instrument casings, and more.

Simultaneously, surface treatments such as chrome plating, painting, powder coating, and others can enhance the durability of zinc alloy die-cast components.

Zinc alloy die-casting is utilized in the production of housings and brackets for communication equipment, providing excellent protective performance and structural strength.

Yontone manufactures custom smart cell phone casting, smart watch casting, and housing for laptops by zinc die casting process.

Related Manufacturing Services

Below is the comparison of zp410 vs zl430 vs zamak 2 vs zamak 3 vs zamak 5 vs zamak 7 in their properties, compositions, and applications:

Comparison of Die-Casting Zinc Alloy Grades |

||||||

| Feature | zp410 | zl430 | zamak3 | zamak5 | zamak2 | zamak7 |

| Composition Highlights | Extremely low copper content | Higher copper content | Low copper content | Higher copper content | Higher copper content |

Very low copper content

|

| Performance Highlights | Good fluidity, plasticity, and corrosion resistance | High strength, hardness, and wear resistance | Excellent overall performance; good casting, mechanical, and corrosion resistance | Higher strength and hardness, lower elongation | Higher strength and hardness, slightly lower toughness |

Good fluidity and creep resistance

|

| Application Scenarios | Complex, high-precision, and corrosion-resistant parts | Parts requiring high strength, hardness, and wear resistance | Wide range of die-cast parts (automotive, hardware, toys, etc.) | Parts under higher loads (steering components, pump housings, valve bodies) | Parts requiring high strength and hardness |

Precision parts and those requiring creep resistance

|

| ASTM (US) | – | – | ASTM B240 Alloy AG40A | ASTM B240 Alloy AC41A | – |

ASTM B240 Alloy ZA8

|

| EN (Europe) | – | – | EN 1774-ZnAl4 | EN 1774-ZnAl4Cu1 | – |

EN 1774-ZnAl4Mg1

|

| JIS (Japan) | – | – | JIS H5302 ZDC2 | JIS H5302 ZDC1 | – | – |

Performance Comparison |

||||||

| Property | zp410 | zl430 | zamak3 | zamak5 | zamak2 | zamak7 |

| Tensile Strength (MPa) | ≥ 260 | ≥ 280 | ≥ 265 | ≥ 300 | ≥ 290 | ≥ 250 |

| Yield Strength (MPa) | ≥ 180 | ≥ 200 | ≥ 200 | ≥ 210 | ≥ 210 | ≥ 180 |

| Elongation (%) | ≥ 10 | ≥ 8 | ≥ 10 | ≥ 7 | ≥ 5 | ≥ 12 |

| Hardness (HB) | 80-90 | 90-100 | 85-95 | 90-100 | 90-100 | 75-85 |

| Density (g/cm³) | 6.7 | 6.7 | 6.7 | 6.7 | 6.7 | 6.7 |

| Melting Point (℃) | 380-400 | 380-390 | 380-385 | 380-385 | 380-390 | 380-385 |

Composition Comparison (Weight Percent) |

||||||

| Element | zp410 | zl430 | zamak3 | zamak5 | zamak2 | zamak7 |

| Aluminum (Al) | 3.5-4.5 | 3.5-4.5 | 3.5-4.3 | 3.5-4.3 | 3.5-4.5 | 3.5-4.5 |

| Magnesium (Mg) | 0.02-0.05 | 0.02-0.05 | 0.02-0.08 | 0.02-0.08 | 0.02-0.1 | 0.01-0.03 |

| Copper (Cu) | ≤ 0.02 | 0.5-1.5 | 0.7-1.1 | 0.7-1.1 | 0.5-1.2 | ≤ 0.1 |

| Iron (Fe) | ≤ 0.035 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.02 |

| Lead (Pb) | ≤ 0.002 | ≤ 0.005 | ≤ 0.005 | ≤ 0.005 | ≤ 0.005 | ≤ 0.003 |

| Cadmium (Cd) | ≤ 0.002 | ≤ 0.005 | ≤ 0.005 | ≤ 0.005 | ≤ 0.005 | ≤ 0.003 |

| Tin (Sn) | ≤ 0.001 | ≤ 0.001 | ≤ 0.001 | ≤ 0.001 | ≤ 0.001 | ≤ 0.001 |

| Zinc (Zn) | Balance | Balance | Balance | Balance | Balance | Balance |

Yontone has over 20 years of experience in zinc alloy die casting. We assist customers in choosing the right zinc alloy for their die-cast parts based on factors such as part shape, precision requirements, operating environment (corrosion resistance, strength), and cost.