Top Quality with Reasonable Price

- Ningbo Beilun YONTONE Hydraulic Technology Co., Ltd. (referred to as “YONTONE”) is an OEM mould making, die casting, casting, and CNC machining manufacturer for many world-famous brands and companies. Such as Bosch, Metabo, Jcb, Phillips, etc. We design, make, and optimize moulds, die casting, casting, and machining processes.

- The competitiveness and the high quality of our products are achieved primarily due to our exploratory development, aimed at mastering new alloys according to customers’ specifications.

- Yontone is a full-supply-chain supplier. We know the flow of each process of mould design, making, die casting, casting, and CNC machining process. We provide one-stop solution for clients from mould design to finished parts delivery. Through reasonable arrangements, Yontone provides rapid mold development services for urgent orders from clients. Become China’s first 25-day delivery mould factory.

- So far, Our main business: 1. Mould; 2. Die-casting (Aluminum, Zamak, and Brass); 3. Casting (Aluminum, Steel, Iron);4. CNC machining; 5. Surface treatment. Yontone can provide customers with the one-stop solution – from material to delivery.

- Today, Yontone parts are exported to the United States, Germany, Japan, Italy, France, Spain, Saudi Arabia, New Zealand, etc. Clients from more than 20 countries, and over 5 continents, and the quantity of our customers is still increasing…… Welcome to visit our company!

Main OEM Services - Product Show Case

Best Solution Supplier – from material to delivery!

Design Engineering Ability

With CAD designers and CAM programmers who work in mould design field for more than 8 years. We provide the documents below:

- Direct import of 3D scanning data for reverse engineering ( if customers don’t have product drawings, only a sample.)

- Mold development task book

- Mould BOM list

- Mold making schedule

- Create 2D drawings and 3D models

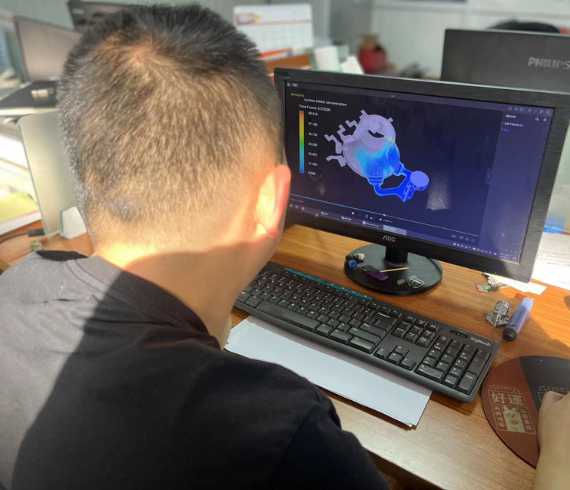

- Moldflow simulation & analysis ( 3D print for the prototype of mould design, if needed)

- Trial-out Process Card

- Mold Acceptance Checklist

- Product size inspection report

Compared with those suppliers who only do mold business, our production experience in die casting and machining helps us to produce molds with more reasonable structure & higher production efficiency.

.

Mould Making Workshop

- Yontone has High-Speed CNC Machining Center, Wire Electrical Discharge Machine (Wire-EDM), Electrical Discharge Machine(EDM), Engraving Machine, Grinding Machine and Died Spotting Press.

- Our mold-making capacity for aluminum die casting mould is: from 180 tons to 2000 tons.

- Our mold making capacity for zinc die casting mould is: from 25 tons to 700 tons.

Die Casting Workshop

- Yontone has Cold Chamber Die Casting Machine and Hot Chamber Die Casting Machine.

- Aluminum Hot Chamber Die Casting Machine sizes: from 180 tons to 2000 tons.

- Zinc Hot Chamber Die Casting Machine sizes: from 25 tons to 700 tons.

Machining Workshop

- Yontone has CNC Milling Machine, CNC Turning Machine, and Drilling and tapping machine..

- Our machine is suitable for machining aluminum alloy die castings (ADC12, A380, A356, AlSi9Cu3, AlSi12Fe), zinc die casting parts (Zamak 3, Zamak 5), iron casting parts (HT200, HT400, QT500, QT600), steel casting parts (C45, C20).

- In addition, we can also directly machine products on the raw materials of the aluminum block (2024, 6061, 7075 T6), iron bar, steel tube (C45, C20, A3, 42CrMo, etc.), brass, copper, magnesium alloy, and titanium alloy.

In-Site Checking Room

- Yongtong has a Three-Coordinate Machining (CMM), Hardness Meter, Roughness Meter, etc. testing equipment.

- We use three coordinates to ensure the precision of die casting die and the dimensional accuracy of die casting products after processing.

- We will provide full-size reports of products, material reports of products, and heat treatment reports of molds when shipping.

For Metal Parts

Yontone is an expert one stop solution provider in mould making, die casting, casting, CNC machining part, and surface treatment. Before mould making we will submit the design and mould flow analysis. To you, 0% trouble and 100% safe to place order with Yontone. Send us a drawing, we will do the rest. Will you be our next client?

Applications, Mould, Die casting, Casting, CNC Machining Parts can be Customized.

Aluminium Die Casting Light Housings: LED Street light housing, Flood light housing, Garden light housing, Factory light housing, Solar light housing, etc.

Also different types of heat sinks for lights.

Aluminium Die Casting Power Tool Housings: Head cover of Polish Machine; Cover of Saw Chain; Housing of Angle Grinder, Electric Drill, Impact Wrench, Jigsaw, Miter Saw, Nailer, Router, Sander, Screwdriver, Shear, Stapler and Housing of Trimmer

Aluminum Alloy Die-Casting (Automobile) Automotive Parts: Oil pans; Brake assemblies, including calipers and brackets; Engine components, including cylinder heads, engine blocks, and transmission cases; Suspension components, including control arms, steering knuckles, and shock absorber housings.

Many zinc alloy die-cast parts are usually used as handles. The door handles and faucet handles in the picture and the main body of the faucet are all made of zinc alloy die casting. Generally speaking, the surface treatment of zinc alloy die casting is polishing chrome coating for faucet parts and powder coating for door handles.

Aluminum Alloy Die Casting Industrial Housings. Engine housing, Transmission housing, are used in power systems, automotive & heavy machinery. Pump housing & compressor housing are used in industries like HVAC (heating, ventilation, & air conditioning), oil & gas, and chemical processing. Motor housing & generator housing can be found in power generation and renewable energy industries.

Aluminum Die Casting Cookware: aluminum frying pan; aluminum grill pan; aluminum wok; aluminum saucepan; aluminum casserole dish; aluminum Dutch oven; aluminum roasting pan; aluminum paella pan; aluminum crepe pan; aluminum sauté pan. And Die Casting Five Star Swivel Chair Base.

Get an Instant Quote

-

How We Grow Up To Be A Trustworthy Business Partner

January 1, 1987, Mould Factory Found

Ningbo Beilun YonTone Mould Factory was established in Ningbo, China.

The main business is: die casting mould design & making.

-

January 19, 1998, Aluminum Die Casting Service Added

aluminum die casting, sandblasting, light housing die casting, flood light housing die casting, die casting mould Aluminum die casting service was added to Yontone’s business scope.

-

July 25, 1999, Zamak Die Casting Service Added

Hot Chamber Zamak Die Casting Moulds and Parts Zamak die casting service was added to Yontone’s business scope.

-

August 6, 2008, Casting, Die Casting & CNC Machining

Cnc Machining Milling WorkshopNingbo Beilun Yontone Hydraulic Technology Co., Ltd was founded by boss Junior. The company’s business scope has been expanded: Mould, Die Casting, Casting, and CNC Machining processes.

-

Feb 10, 2010, One-Stop Solution

Yontone is committed to providing customers with one-stop solution.

From mold design, mold flow analysis, die casting design, casting, die casting, CNC machining, surface treatment & consolidation delivery services.

-

March 12, 2021, Customer All Over the World

Clients Visiting Sales@yontone.com Today, Yontone has served customers in more than 20 countries, 5 continents, US, Germany, Japan, Italy, France, Spain, Saudi Arabia, etc. and the quantity of our customers is still increasing. . .

-

Yontone has been our reliable partner for a while now. Their commitment to producing top-notch die-casting moulds, their punctuality in delivering orders, and their exceptional customer service have all made us very happy.

When it comes to product quality, on-time deliveries, and exceptional customer service, Yontone truly stands out. We are thoroughly satisfied with our collaboration with them and highly recommend their services.

Jason HaltermanLakeville, MN

Jason HaltermanLakeville, MN -

Working with Yontone has been a delight. Their aluminum die-casting parts consistently exceed our expectations in quality and precision. Their punctuality is unmatched, a crucial factor in our industry. Their customer service is exceptional, always going the extra mile.

Overall, we’re thrilled with Yontone. Their quality, on-time deliveries, and service make them a top-tier supplier. Looking forward to our continued partnership.

Jeff TranthamHendersonville, NC

Jeff TranthamHendersonville, NC -

Yontone has been an outstanding partner in delivering high-quality CNC machining parts. Their unwavering commitment to excellence, fast deliveries, and exceptional customer service have greatly impressed us.

We’re extremely satisfied with Yontone. They excel in terms of product quality, meeting deadlines, and providing outstanding customer service. We couldn’t be happier with our partnership!

John BradburyCity of Cape Town

John BradburyCity of Cape Town